Steam Heating Systems Part 5: Spring Pilot Operated Pressure Valves

/By Mark Bingham

For precise and stable control of steam pressure, particularly under widely fluctuating loads, a pilot-operated pressure reducing valve (PRV) is superior to a simple direct-acting valve. The "brain" of this system is the spring pilot, which acts as a highly sensitive controller that tells the larger main valve how to modulate.

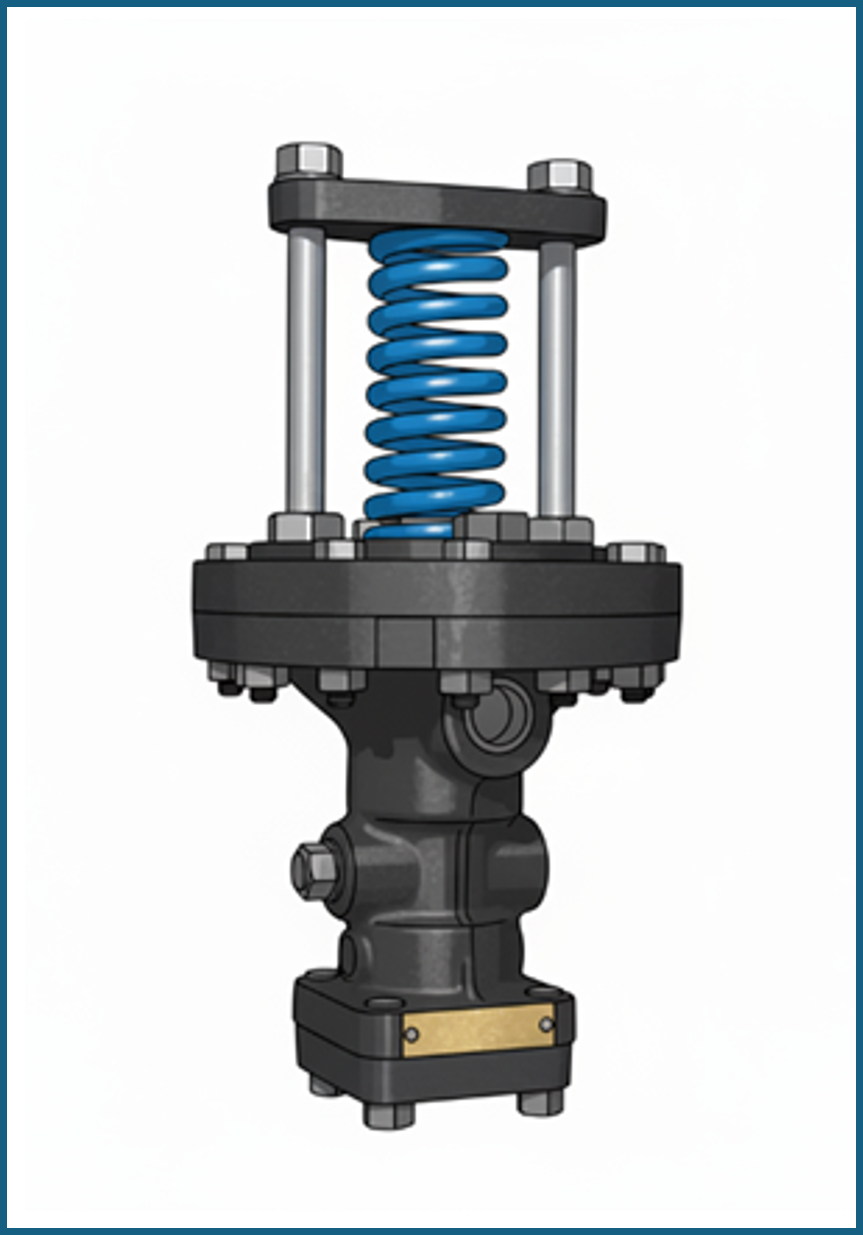

Figure 1. Hoffman Spring Pilot

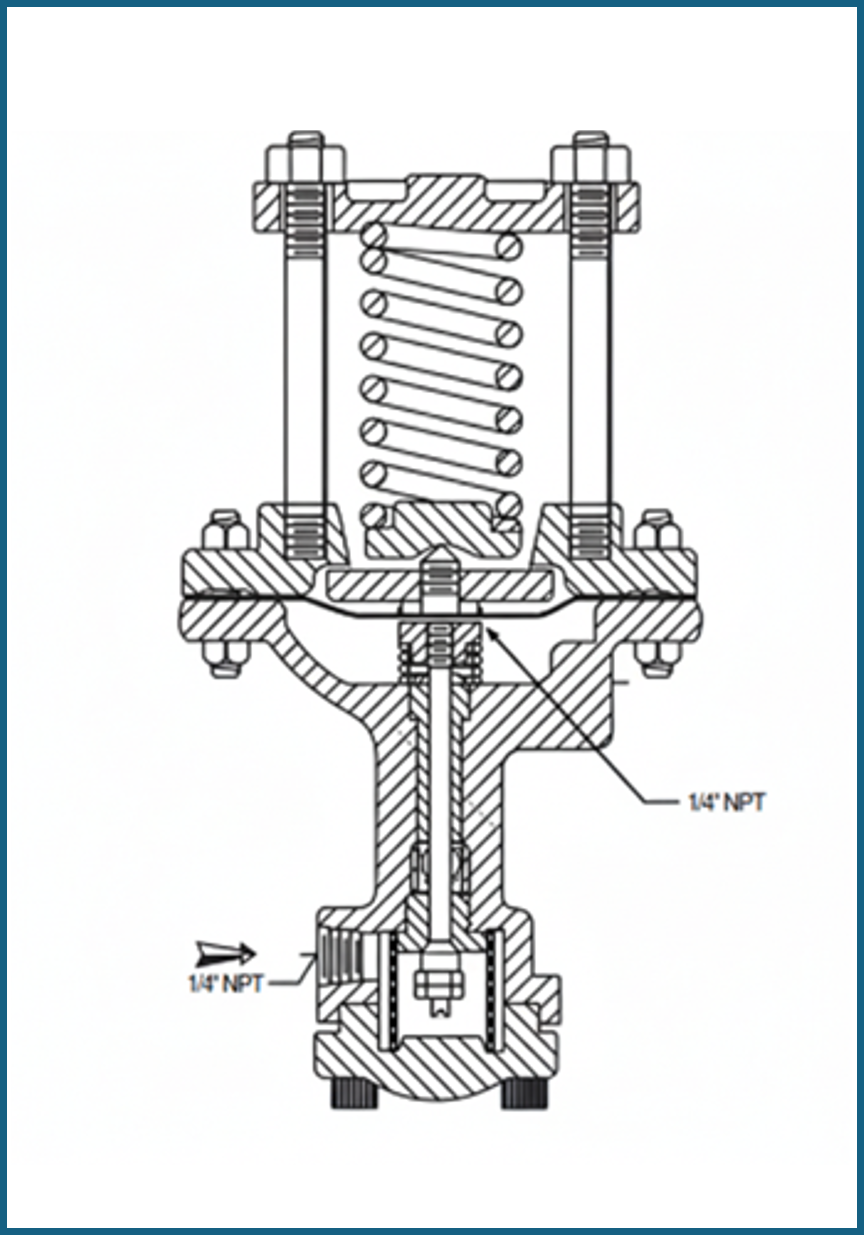

Figure 2. Hoffman Spring Pilot Cross Section

Spring pilots operate on a force-balance principle. The pilot senses the downstream steam pressure, comparing it to the desired setpoint and then responds by driving the valve stem up or down maintain setpoint.

The pilot consists of:

Spring: Provides the force to open or close the valve. The control setpoint is set by adjusting the compression of the spring using nuts on the top of the pilot.

Plug and Seat: Regulates the flow of steam to the main valve actuator.

Diaphragm: Senses the downstream pressure and moves the stem and plug in response to the setpoint. When the sensed pressure is below the setpoint, the spring drives the stem and plug down, increasing steam flow through the pilot to the main valve diaphragm. When the sensed pressure is above setpoint, the diaphragm pulls the stem and plug up, reducing the flow to the main valve diaphragm.

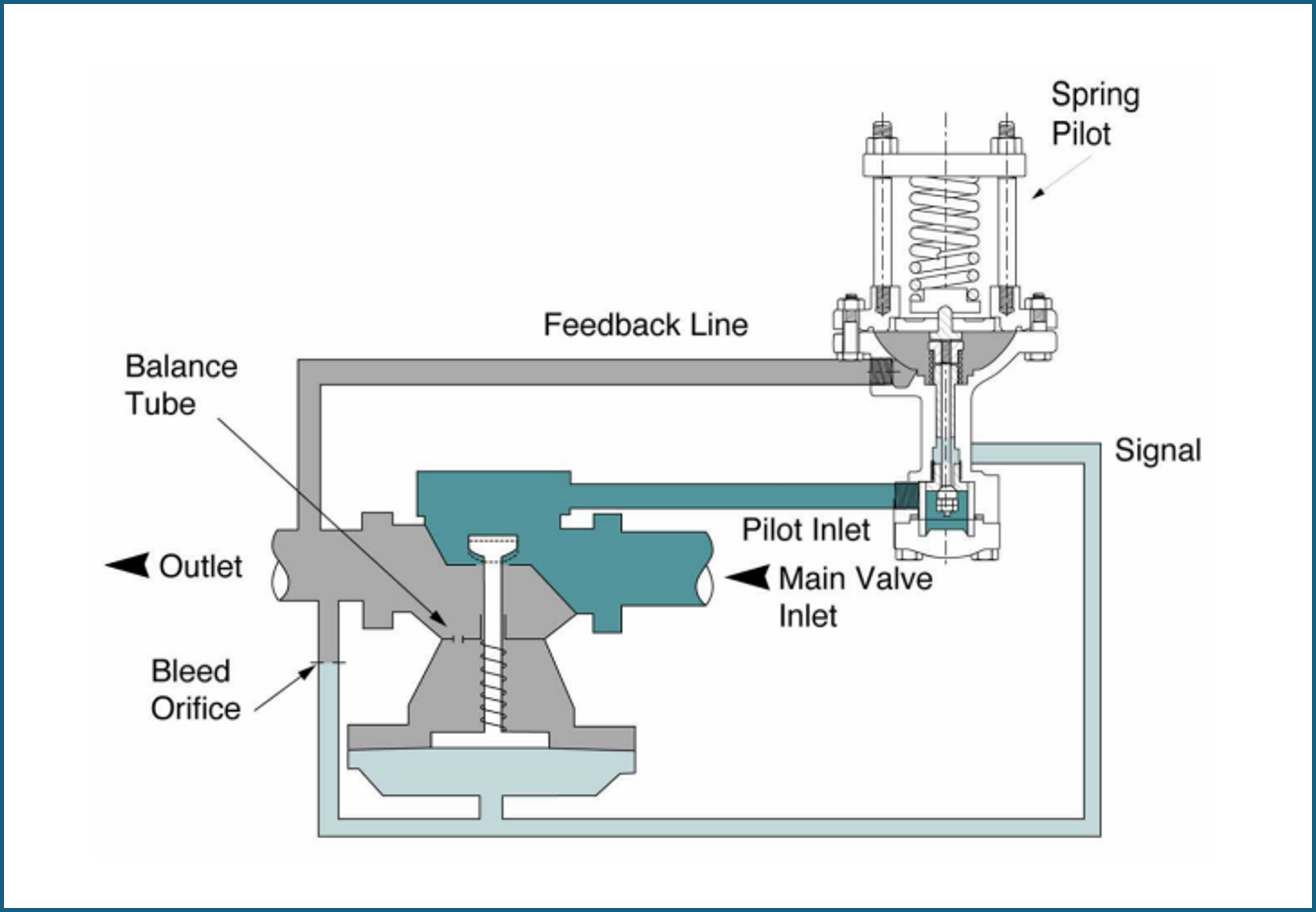

Figure 3. Schematic of a Pilot Operated Valve

Installation

1. Sensing Line (Piping)

The pilot must sense the downstream pressure. This is accomplished via an external sensing line, which is typically ¼ in. piping. The sensing line must be connected to the downstream piping, not to the main valve body itself. It should be installed 5-10 pipe diameters downstream, away from the turbulence created by the PRV and downstream valve and fittings to get a stable and accurate pressure reading. The sensing line must be pitched away from the pilot to allow for condensate to drain properly. The sensing piping should include an isolation valve and a union to facilitate removal of the pilot for service or replacement.

2. Control Tubing

This tubing connects the pilot to the underside of main valve diaphragm and to the bleed orifice. The pilot uses high-pressure steam from the inlet side of the main valve, throttles it, and sends it through this tubing to pressure load the main valve diaphragm. This pressure loading physically pushes the main valve open. The control tubing is short and supplied with a hardware kit for pilot installation.

3. The Bleed Orifice

The bleed orifice is a critical, and often misunderstood, component. It is a tiny, fixed-size hole that constantly "bleeds" a small amount of loading pressure from the main valve actuator, venting it to the outlet of the main valve.

This constant bleed is essential for the valve to close.

To open the main valve, the pilot lets more steam into the loading chamber than the bleed orifice can vent.

To close the main valve, the pilot restricts the flow of steam into the loading chamber. The bleed orifice then vents the loading pressure, allowing the main valve's spring to push it closed.

To modulate, the pilot finds a balance where the steam flow in equals the steam flow out of the bleed orifice, holding the main valve at a position to maintain the setpoint pressure.

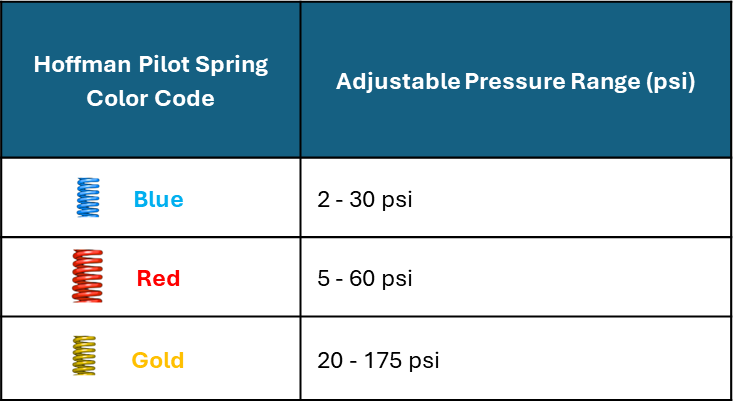

Setting the Pressure: Hoffman Pilot Springs

The controlled downstream pressure range is determined entirely by the pilot spring. Hoffman uses colors to indicate the pressure setpoint ranges for their spring pilots.

Spring pilots play a crucial role in the operation of steam pressure reducing valves by providing reliable and precise control of steam pressure. Their mechanical simplicity and effectiveness make them a preferred choice in many applications. Understanding their function can help optimize steam systems safety and performance.