How To Size A Waterside Economizer Part 1: How ASHRAE 90.1 – 2010 and 2013 Have (Or WILL) Change Chilled Water Design

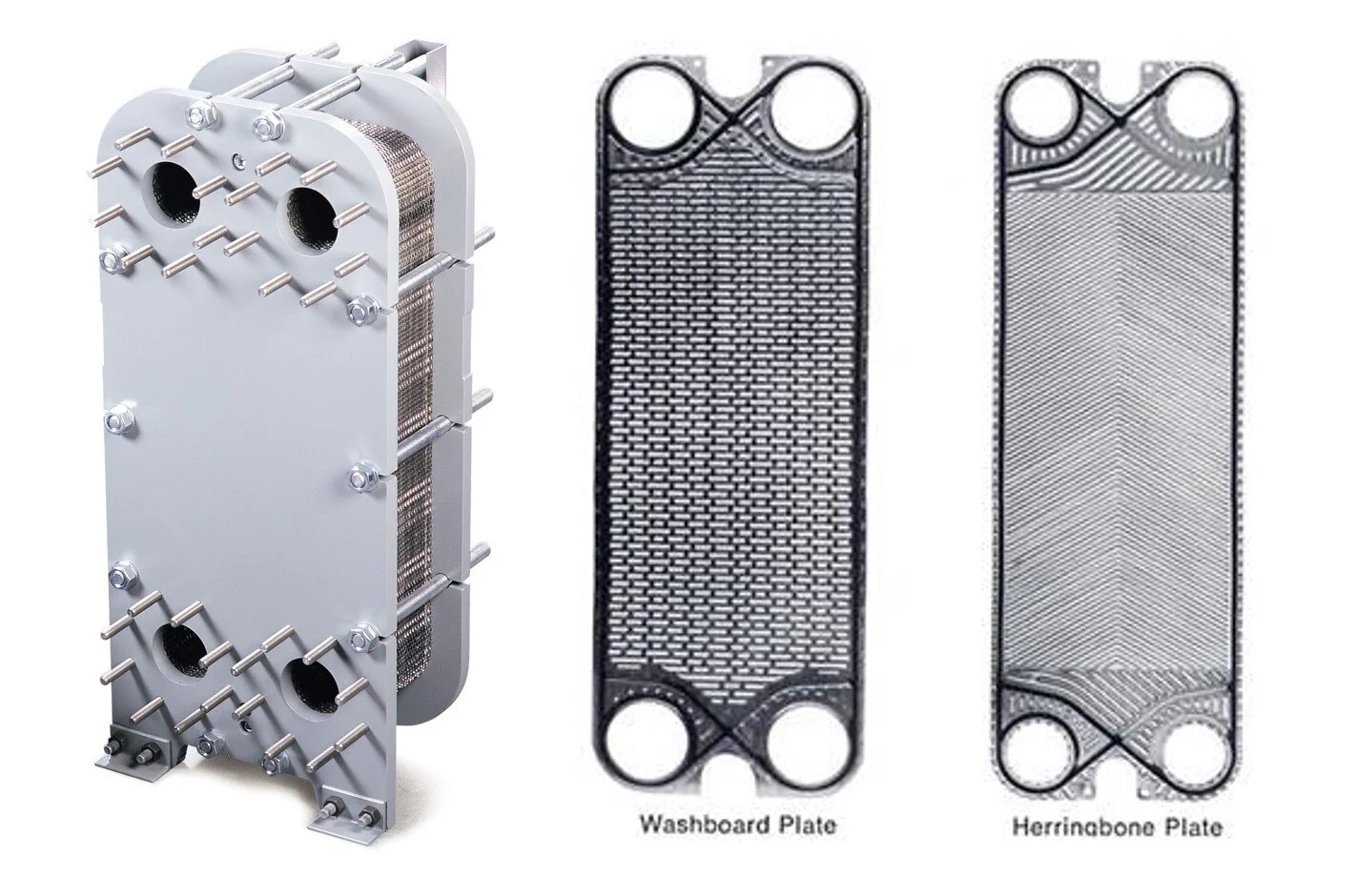

Waterside economizing typically involves the transfer of BTUs from an open loop cooling tower system to a closed loop chilled water system. Since these two hydronic systems must remain separate so we do not foul the chilled water systems, a heat exchanger is required to prevent mixing of the fluids, but what type of heat exchanger should you choose?

In our last blog we discussed heat exchanger piping on the cooling tower/condenser water side of a system with integrated waterside economizing to meet ASHRAE 90.1. Today, we’re going to tackle the chilled water…

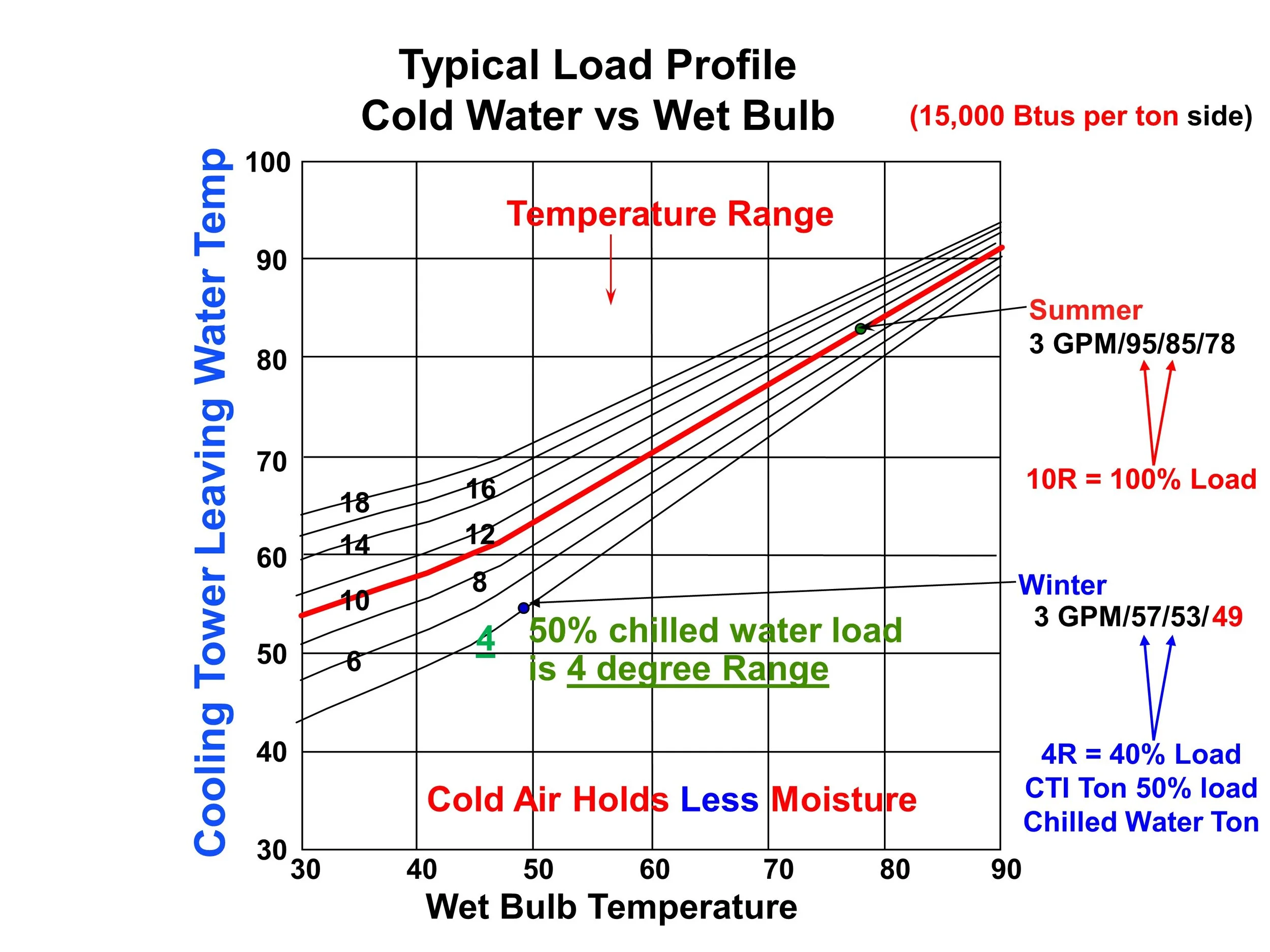

Waterside economizing relies on cold water from the cooling tower (aka condenser water) to absorb some or all of the heat from inside the building. In typical waterside economizing applications, plate & frame heat exchangers are used to…

Hold the phone; we’re about to blow your mind.

Did you know it can take a larger cooling tower to perform the same amount of cooling when it’s cold outside than when it’s hot?

Has your state adopted ASHRAE 90.1-2010 or beyond into its commercial building code? If so, then it is highly likely that you should be incorporating either waterside or airside economizing into your cooling design. The Standard has effectively made air or waterside economizing a requirement in virtually every…

Approach temperature and an AHRI 400 rating are probably the two most critical factors when it comes to selecting a plate and frame heat exchanger for maximum efficiency and guaranteed performance. Do yourself and your client a favor and…