Steam Heating Systems Part 4: Pilot Operated Steam Pressure Reducing Valves

/Steam Heating Systems Part 4: Pilot Operated Steam Pressure Reducing Valves

By Mark Bingham

Pilot operated steam pressure reducing valves (PRVs) offer superior performance compared to direct-acting regulators in systems with wide capacity ranges that require precise pressure regulation. Unlike their direct-acting counterparts, which rely solely on spring force and downstream pressure acting on a diaphragm, pilot operated valves employ a separate pilot control system that provides enhanced sensitivity, accuracy, and flexibility.

Operating Principle

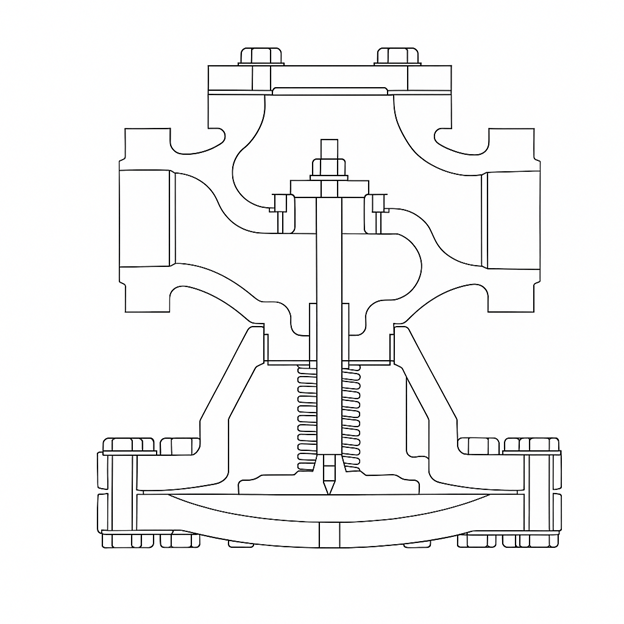

A pilot operated PRV consists of two primary components: the main valve body and the pilot control assembly. The pilot continuously senses downstream pressure and modulates the loading pressure applied to the main valve's diaphragm. This arrangement creates a self-regulating control loop where the pilot acts as the "brain" and the main valve serves as the "muscle" of the pressure reduction system.

The key advantage of this configuration is that the pilot requires minimal force to reposition the main valve, allowing for:

Rapid response to pressure fluctuations

Precise control over wide flow ranges

Tighter pressure regulation (±1-2 psi achievable)

Larger main valve sizes for larger loads with the same pilot size.

Construction and Composition

The primary parts of the main valve body are:

Valve Body. Cast iron or forged steel construction with flanged or threaded connections.

Plug and Seat. The throttling element consists of a precisely machined plug (or disc) that modulates against a seat ring. Materials are selected for erosion and wire-drawing resistance. Valves by Hoffman and other manufacturers can be fitted with three different port sizes in the main body—full, normal and reduced ports. These ports can be changed in the field if a capacity change is required. The metal-to-metal seat conforms to ANSI FCI 70-2 Class IV which allows for a leakage of 0.01% of rated capacity. This small leakage is usually offset by heat losses downstream of the main valve. Systems with minimal surface area downstream of the valve can experience pressure creep at low loads.

Diaphragm. Provides the motive force to position the plug. Diaphragms are typically multi-layer stainless construction with large effective areas to generate substantial actuating force.

Valve Stem. Connects the actuator to the plug, transmitting positioning forces. Features include stem guides or bushings to prevent side-loading and ensure linear travel.

Spring Assembly. Provides fail-safe positioning (fail-closed for safety) and assists in valve closure when inlet pressure drops below the set point.

Figure 1 illustrates the internal arrangement of a Hoffman pilot operated steam PRV. Figure 2 shows exterior of a Hoffman PRV.

Figure 1. Pilot Operated Steam PRV Cutaway

Figure 2. Hoffman 2100 Threaded Main Valve

Overpressure Protection

If downstream pressure exceeds setpoint due to external heat sources, back-pressure, or oversized valve selection, the pilot responds by:

Reducing loading pressure from the actuator chamber

Allowing the main valve spring to close the plug

Restricting flow until downstream pressure returns to setpoint

This self-regulating action provides inherent overpressure protection without external safety devices, though dedicated safety relief valves are still required per code. The relief valve(s) must be selected to relieve the maximum flow of the valve(s) with a full port seat(s) since it is possible to replace seats in the field. A future article will discuss steam safety relief valves.

Performance Characteristics

Turndown Ratio. Turndown ratio is the ratio of maximum normal flow to minimum controllable flow. Pilot operated valves typically achieve turndown ratios of 50:1 or greater, significantly exceeding the 10:1 to 20:1 range of direct-acting designs. This wide rangeability stems from the pilot's ability to apply variable loading pressure independent of flow rate, maintaining stable control from minimum to maximum capacity.

Pressure Regulation Accuracy. Regulation accuracy (droop) describes how much downstream pressure varies between no-flow and full-flow conditions. Pilot operated valves typically exhibit a 2 - 5% droop. By comparison, direct-acting valves typically show 10 - 15% droop.

Response Speed. The pilot's low mass and high sensitivity enable rapid response to pressure transients—typical response times range from 0.5 to 2 seconds for a full stroke, depending on main valve size and pressure differential. This quick response minimizes pressure fluctuations during rapid load changes.

Flow Capacity. Flow capacity is determined by valve size, trim selection, and pressure differential. While catalog data shows capacities for various differential pressures, selection is best done with a computer selection program. The selection program indicates flow with the largest orifice that the body may be fitted with as well as the maximum sound level at 3 feet. OSHA standards require the sound not exceed 85 dB at three feet from the valve. The largest possible flow rate is required for selecting proper safety relief valves.

Hoffman pilot operated valves are available in sizes from 1/2" through 6", with flow capacities from hundreds to tens of thousands of pounds per hour.

Installation Requirements

Proper installation is critical for optimal performance:

Upstream Piping. Install a minimum of 10 pipe diameters of straight run upstream to ensure developed flow profiles. Include a separator or steam strainer (40-60 mesh) to remove particulates and condensate that could damage the trim or plug sensing lines.

Downstream Piping. Provide at least 5 pipe diameters downstream before elbows or fittings. Install the downstream sensing line 6-10 pipe diameters downstream to sense stabilized pressure.

Pilot Sensing Line Connections. Pitch sensing lines downward from the takeoff point to the pilot, installing drip traps at low points to prevent condensate accumulation.

Bypass Configuration. Install a hand-operated bypass valve for maintenance and emergency operation.

Isolation Valves. Provide full-port block valves upstream and downstream for service isolation. Include a vent/drain connection (usually as a strainer blowdown) downstream of the inlet isolation valve.

Common Failure Modes:

Plugged sensing lines (causing erratic control or failure to respond)

Diaphragm rupture

Trim erosion from wet steam or excessive velocity

Advantages Over Direct-Acting Designs

Pilot operated valves offer several advantages:

Superior Accuracy. Regulation within 1-2% vs. 10-15% for direct acting

Wider Rangeability. 50:1+ turndown vs. 10-20:1

Faster Response. Sub-second actuation vs. 2-5 seconds

Larger Capacities. With main valves up to 6-in. with full port trim vs. 1-in. self-contained valves.

Better Low-Pressure Performance. Where spring force may provide poor performance in self-contained valves.

Serviceability. Replaceable trim and external pilots simplify maintenance

Pilot operated steam pressure reducing valves provide precise, reliable pressure control for demanding industrial applications. Their two-stage architecture—combining a sensitive pilot control system with a robust main valve—enables performance characteristics unattainable with simpler direct-acting designs. While initial costs are higher and installation complexity increases due to external sensing lines, the operational benefits of accuracy, rangeability, and maintainability justify their selection in many steam systems.