Parallel Pumping with Optimized Impeller Pumps Part 3: Optimizing Single Pump Performance

/Optimized impeller pumps with variable frequency drives are often capable of flow and head above the specified conditions of service. In this blog, we demonstrate how a thoughtfully selected optimized impeller pump can provide more flow and higher efficiencies than a traditional trimmed impeller pump when operating without the second pump in a parallel pumping arrangement.

For our first example, let’s say we enter a selection for a traditional constant-speed parallel pump for 900 gpm at 65 feet into Bell & Gossett’s ESP-Systemwize selection tool. This input yields an e-1510 3BD pump with an 8.625-inch impeller and a non-overloading 15 HP motor, operating at 1770 rpm with an 82.3% design point efficiency (Figure 1). This selection produces a single pump flow of 700 gpm (Figure 2).

Figure 1. ESP Systemwize Output for 900 gpm at 65 feet, 2-Pump Parallel Operation

Figure 2. Single and Parallel Pump Curves for Selection Above

If we change our selection to variable speed, we get the same pump and motor as above but a full-diameter (9.5-inch) impeller. This gives us a higher design point efficiency of 84.3% when operating at 1585 rpm (Figure 3).

Figure 3. ESP Systemwize Output for 900 gpm at 65 feet, 2-Pump Parallel Operation with Optimized Impellers

Better yet, this pump's singular operation at its nominal 1770 rpm speed provides approximately 795 gpm flow while still operating below the motor nameplate rating (Figure 4).

Figure 4. Single and Parallel Pump Curves for Optimized Impeller Selection Above Operating at 1770 rpm

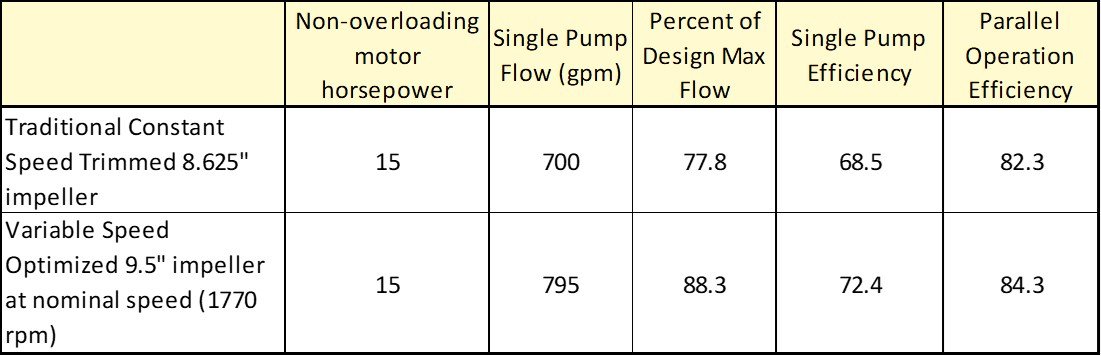

This optimized selection results in a 2% efficiency gain and a single pump flow increase of almost 100 gpm at no extra cost to the owner (Table 1). This pump can safely operate at a speed above 1770 rpm and provide even more flow.

Table 1. Summary of Traditional and Optimized Impeller Selections for 900 gpm at 65 feet

When Two Pumps Are Better than One

While operating a single pump can meet the system demand most of the time, it is sometimes more efficient to operate both pumps, each delivering half the demand flow. Systemwize can display the respective efficiencies of pump combinations at 25%, 50%, 75% and 100% design flow (Table 2). If a flowmeter is present, the building management system can stage the pumps for improved efficiency per this staging information. Table 2, based on the optimized impeller pump selection above, indicates that operating two pumps at 50% design flow will result in improved system efficiency of 81% versus 79.5%.

Table 2. Best Efficiency Staging Output from Systemwize

Optimization PLUS an Up-sized Motor

Sometimes, we can get even more single-pump capacity by slightly upsizing the motor. Let’s say we use Systemwize to select a traditional constant-speed parallel pump for 500 gpm at 65 feet. Setting the number of pumps to two gives us two e-1510 2.5BB pumps with 8.625-inch impellers operating at 1750 rpm (synchronous speed) with a non-overloading 7.5 hp motor (Figure 5).

Figure 5. ESP Systemwize Output for 500 gpm at 65 feet, 2-Pump, Parallel Operation

The resulting parallel pump curve shows a single pump can provide a flow of about 385 gpm (Figure 6).

Figure 6. Parallel Pump Curve for Traditional Selection Above

Now, if we select variable-speed pumps with optimized impellers for the same conditions, we get two pump choices: one with a 9.5-inch impeller and the other with an 8.75-inch impeller (Table 3).

Table 3. Optimized Impeller Options for Selection Above

The pump selection with the 8.75-inch impeller selection has the same 7.5 horsepower motor, but the impeller diameter increases by 1/8-inch over the constant speed (8.625-inch impeller) selection. In this selection, the single pump efficiency increases by 0.2%, and the full flow efficiency increases by 0.1%. The single pump flow also increases by about 10 gpm when it operates at its nominal 1750 rpm (Figure 7). While these changes in efficiency and flow are not large, they come at no extra cost, assuming a VFD was to be provided with either selection.

Figure 7. Variable-speed pump selection, plus a slightly larger impeller, improves flow over constant-speed selection for the same design service.

Now, let's see what happens when we opt for an optimized impeller pump selection with a larger motor for the same system as above. Systemwise gives us the option for a 9.5-inch (full diameter) impeller pump with a 10-horsepower motor (Figure 8). This significantly improves single pump flow and design point efficiency. Our duty point efficiency is now up to 77.7%, and our single pump flow is up to 438 gpm when operating at its nominal speed (Figure 9). These gains will likely offset the cost increase of opting for a 10-horsepower pump over a 7.5-horsepower pump.

Figure 8. ESP Systemwize Output for 500 gpm at 65 feet, Optimized Impeller, 2-Pump Parallel Operation

Figure 9. Full diameter impeller pump operating at nominal 1750 rpm

With the full diameter 10-horsepower selection, we have yet another option to increase the single pump flow by allowing operation at the highest possible speed to fully load the motor. Running at 1780 rpm, the single pump flow increases to 445 gpm (Figure 10). The efficiency at the 500 gpm design flow remains the same as the 10-horsepower, 1750 rpm limited selection since the pump speed is reduced to meet the design conditions.

Figure 10. Single Pump Flow with Optimized 9.5" impeller operating at 1780 rpm

If we set the VFD for current limiting operation and allow the full-diameter pump to operate at its maximum non-overloading speed of 1780 rpm, we get a single pump flow of about 445 gpm. Table 4 below summarizes and compares the results of traditional pump selections with optimized impeller alternatives for 500 gpm at 65 feet.

Table 4. Summary of Traditional and Optimized Impeller Selections for 500 gpm at 65 feet

When optimized impeller pumps are specified, the size of the near pump piping and accessories should be chosen for the resulting single pump flows.

In conclusion, larger diameter impellers allow for more flow when a single pump operates in a parallel pump arrangement, and efficiency is improved for both single and parallel pump operation. Further improvements are also possible for some selections by selecting the next size larger motor. Designing a parallel pumping system with readily available stock pumps also provides a potential additional level of redundancy since a replacement pump can be delivered quickly if required.