Boiler Installation Pitfalls Part 4: Hydronic Piping

/Hydronic piping must be designed to let high-efficiency boilers do their thing. No designer wants to unknowingly undermine a boiler’s potential to save an owner money. But many of the variable flow systems we see today are designed in a way that derates the efficiency of condensing boilers.

Condensing boilers need two things to operate at their highest efficiency: (1) low return water temperatures and (2) the ability to operate at the lowest fire given the current demand. These two requirements hinge on the piping design.

The graph in Figure 1 shows how condensing boiler efficiency decreases as the firing rate and return water temperature increase. Although this graph refers to one specific model of boiler, all condensing boilers have this same basic efficiency profile given the firing rate and return water temperature.

Figure 1. Typical Efficiancy Curve for condensing boilers.

Traditional constant speed primary/variable speed secondary design does not support the operational requirements for condensing boilers. They cannot reliably supply consistently lower boiler supply water due to recurrent mixing of hot supply water from the primary loop with lower temperature return water in the common pipe between the primary and secondary loop.

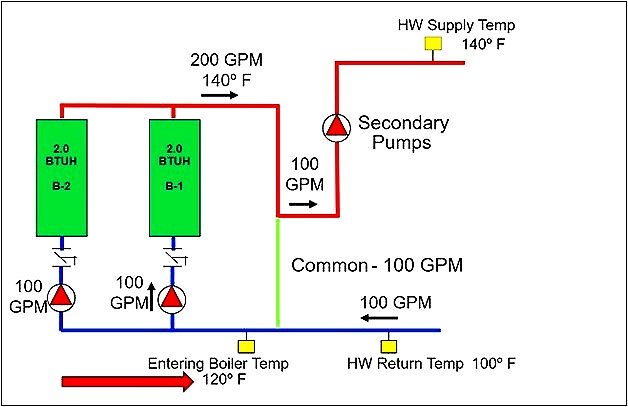

Figure 2 illustrates how this happens. Here we have a fully loaded constant speed primary/variable speed secondary design with 100 GPM supplying the system at 140°F with a return water temperature of 100°F. Both boilers are on, and the primary pumps are pumping 200 GPM. But because the secondary pumps are only pumping 100 GPM (one-half of the 200 GPM being pumped by the primary pumps), another 100 GPM will naturally flow into the common pipe and mix with the 100°F return water. This mixing of 140°F supply water with 100°F system return water drives up the entering boiler temperature up to 120°F. Looking back at the graph, we can see how dramatically the fully loaded boilers and elevated return water temperature impact the boiler’s efficiency. (Remember, this is a constant speed primary loop, so we have two choices to meet load: one boiler flowing 100 GPM or two boilers flowing 200 GPM).

Figure 2. Constant flow primary/variable flow secondary design derates the efficiency profile of condensing boilers due to mixing of water in the common pipe.

Variable primary design (no secondary loop) addresses this problem but adds significant complexity to the control system. For starters, flow limiters are required for each boiler in a multi-boiler system to prevent over-pumping the boiler. Two-way isolation valves are required for each boiler to stop flow through a boiler if it is not running. The isolation valves must be controlled so that one boiler isolation valve or a boiler bypass valve is open, so we don’t dead-head the building pump. Keep in mind that flowing hot water through an off-boiler is a waste of energy due to heat from the water being lost via the stack. We cover this and other control complexities of variable primary systems in our blog, Condensing Boiler Plant Piping Design & Control Part 2: Variable Primary Flow Systems.

Variable Primary/Variable Secondary for Efficient Staging

Because of the above limitations and/or complexities, JMP recommends variable primary/variable secondary design for systems with condensing boilers (Figure 3).

figure 3. Variable primary/variable secondary design enables efficient staging while minimizing mixing in the common pipe. boiler efficiency is maintained as a result of low fire operation and cold return water temperatures.

Having variable flow in both loops:

Simplifies both the control and staging of boilers.

Eliminates the need for flow limiters, boiler isolation valves, or boiler bypass on-off valves.

Saves energy by preventing flow through an off boiler, a condition which results in BTUS radiating from the boiler heat exchanger and out the flue.

Optimizes pump energy by varying the speed of the primary pump and slowing it down when the boiler is at a reduced fire.

Improves boiler efficiency by (1) minimizing the mixing of hot supply water mixing with return water and (2) allowing us to operate multiple condensing boilers at part load.

While variable primary/variable secondary requires an extra set of pumps, the simplicity combined with the efficiency, makes it preferable over both constant primary/variable secondary and variable primary.

(Note: Many boiler manufacturers don’t allow for common venting boilers when practicing efficient staging, i.e., operating multiple boilers at their lowest fire. This is because boilers are more sensitive to pressure changes in the vents and are prone to go off on nuisance trips when they are held at low fire. This can especially be a problem when the boiler plant is oversized.)

Avoid this Non-Condensing Boiler Pitfall

Of course, not all boilers being installed these days are condensing; we still see a fair share of non-condensing boilers, too. The most common pitfall associated with non-condensing boilers is allowing them to condense. A non-condensing boiler that is allowed to condense won’t last very long. To avoid this common pitfall with non-condensing boilers, you must have a cold-water protection valve on the boiler (Figure 4).

figure 4. non-condensing boilers benefit from cold water protection via thermostatic mixing valves.

This valve mixes hot water off the boiler water supply with cold system return water to keep the temperature of the entering boiler water at 140°F or above. These valves have an internal thermostat that automatically mixes the water to this setpoint. This is a simpler solution than traditional 3-way modulating valves which must be wired to a separate sensor.