How To Size A Waterside Economizer Part 2: A Cooling Tower In Winter

/Hold the phone; we’re about to blow your mind.

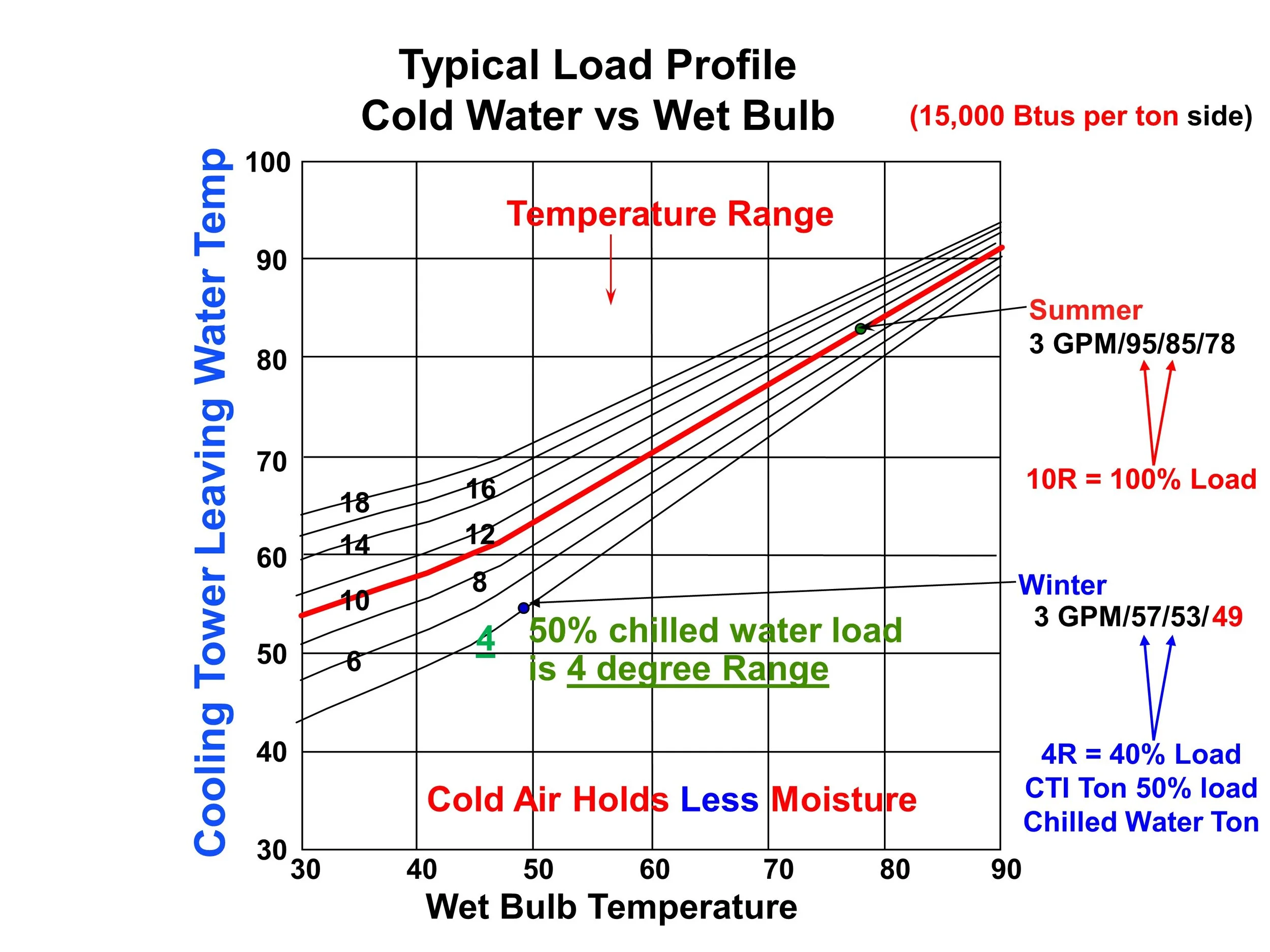

Did you know it can take a larger cooling tower to perform the same amount of cooling when it’s cold outside than when it’s hot?

Read More