Pump Motor Efficiency Part 4: What Is a SMART PUMP?

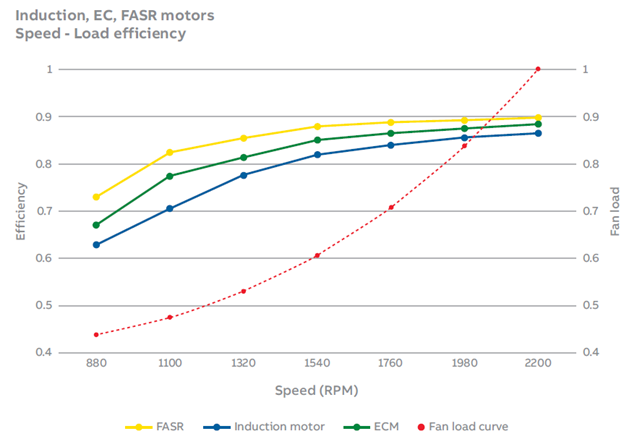

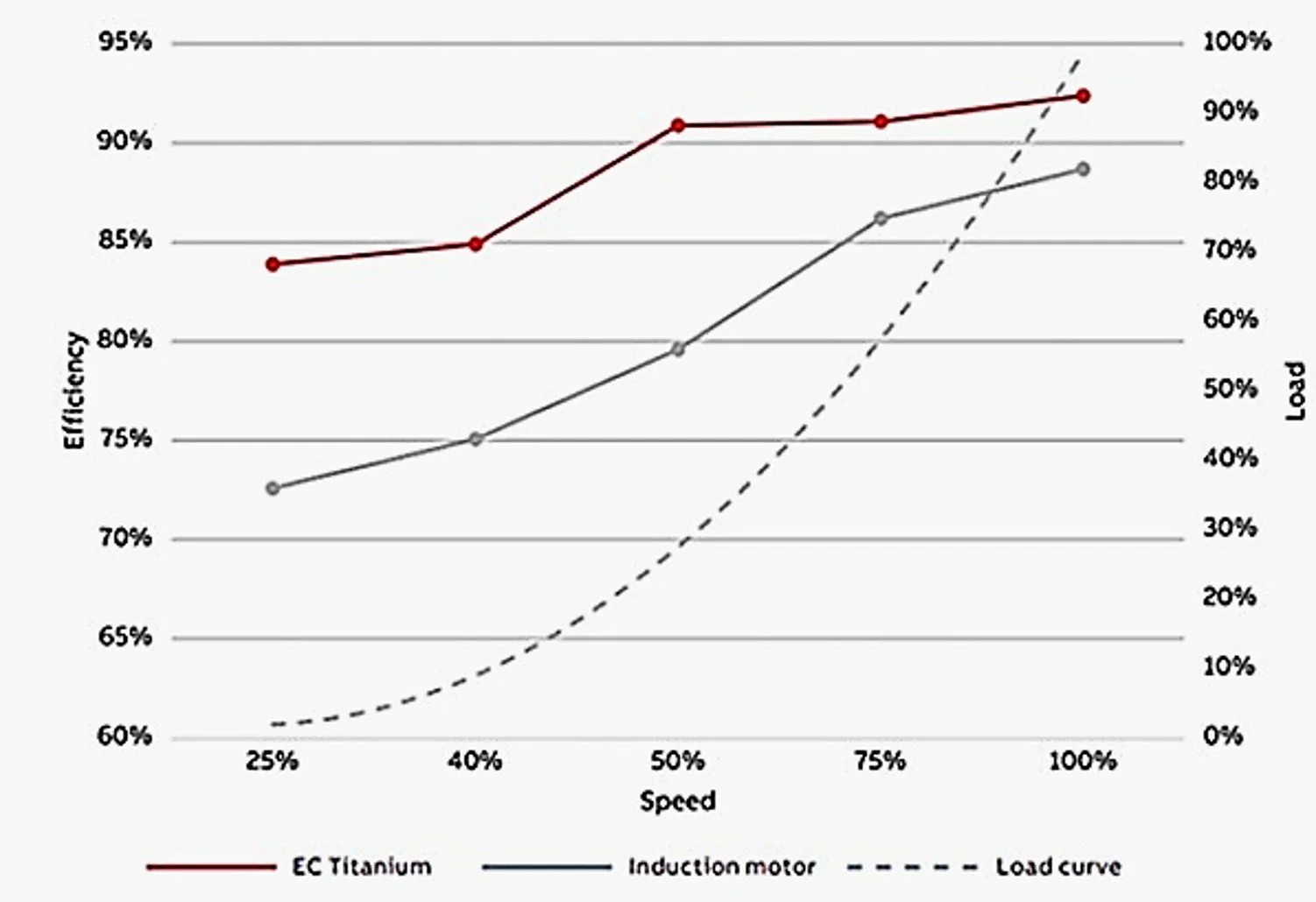

/Perhaps you’ve heard about mandates for higher energy efficiency and the innovations that have emerged to meet these requirements. Integrated control functionality for some HVAC equipment is among these innovations. Fan manufacturers were the first….

Read More