Steam Heating Systems Part 2: Steam Pressure Selection in HVAC applications

/By Mark Bingham

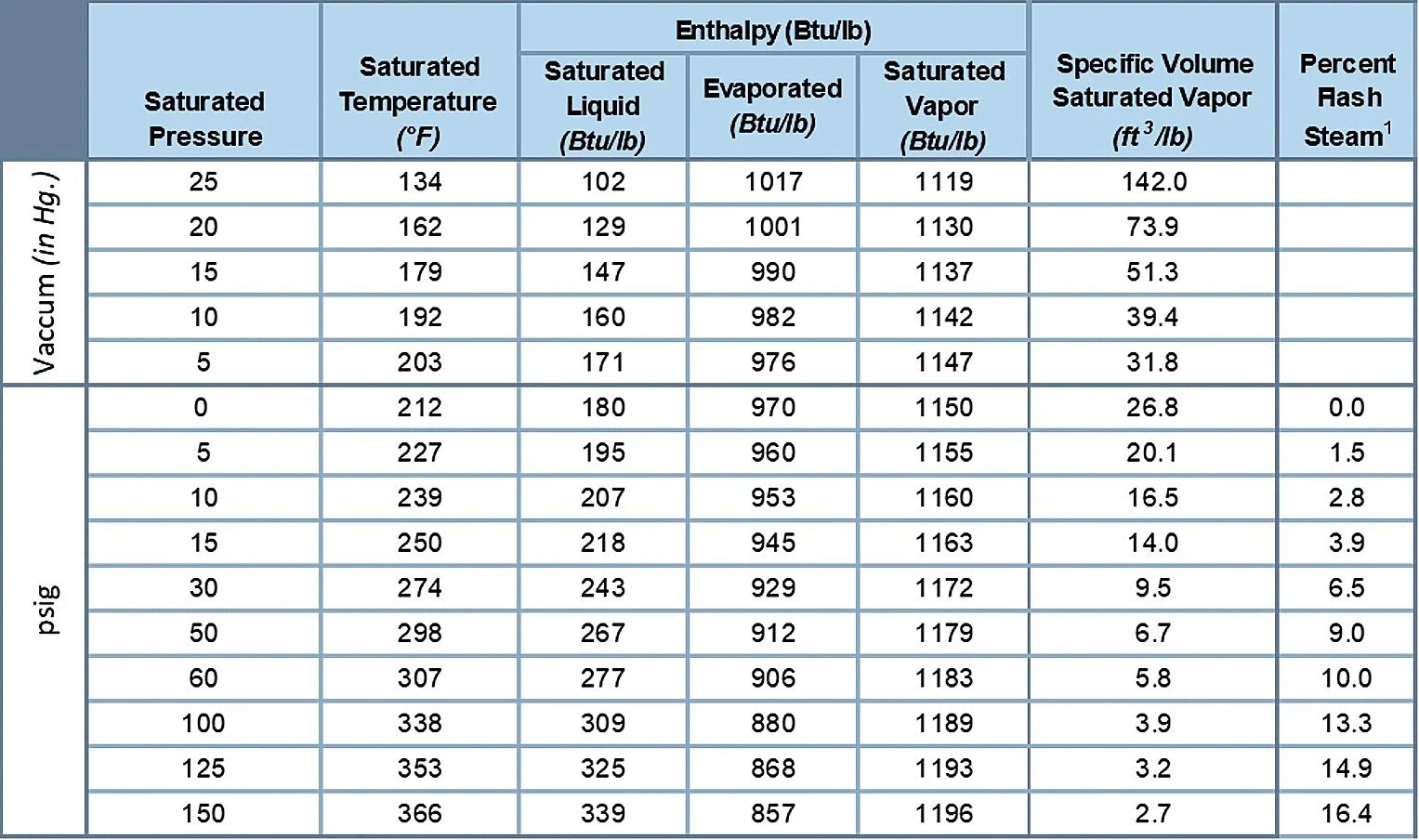

Our series on steam heating systems began with a review of the steam table. Now, let's examine how steam pressure selection affects processes in HVAC systems.

Before we can use steam, it must be generated by a boiler. There are incremental fuel costs associated with increasing boiler steam pressure, but other factors, such as operator licensing requirements—which are based on operating pressure—may also be considerations.

Why to Avoid Unnecessarily High Steam Pressure

The specific volume of steam at 125 psi (3.2 ft³/lb) is less than one-quarter of the specific volume of steam at 15 psi (14 ft³/lb). The lower specific volume of higher pressure steam indicates that the distribution pipes don't need to be as large. However, higher steam temperatures at the higher pressures may result in increased heat losses, and thus the need for higher insulation R-values. Steam leaks at higher pressures waste more steam and result in additional safety concerns. These concerns should be balanced with the lower costs of distribution piping when determining the boiler pressure.

In many cases, the boiler pressure exceeds the desirable (or allowable) pressure for the heating process it serves. In these cases, pressure-reducing valves can be installed near the point-of-use to reduce the pressure. Depending on the steam load and magnitude of pressure reduction required, multiple valves may be indicated. We will discuss various configurations for pressure reduction in a future post.

It may seem intuitive that as steam pressure increases, so does the specific enthalpy of vaporization, but the opposite is true. Looking at the steam table below, we see that 100-psig saturated steam has a specific enthalpy of vaporization of only 880 Btus/lb, while zero-psig saturated steam has a specific enthalpy of vaporization of 970 Btus/lb. Condensing higher-pressure steam yields less heat per pound of steam. It also comes with some additional drawbacks.

Notice in the steam table that the condensate produced when condensing steam at 100 psi has a temperature of 338°F and a liquid enthalpy of 309 Btu/lb. If we subsequently discharge this condensate into a tank or receiver, a large percentage of it will vaporize into steam. Often, this steam is vented to the atmosphere, carrying away water, heat, and water treatment chemicals. The steam that occurs when the pressure is reduced is known as flash steam. We will discuss flash steam and show how to calculate the losses in an upcoming post.

The Upside to Low-Pressure Steam

Condensing steam at lower pressures offers numerous advantages:

The energy content per pound is higher

Flash steam losses are minimized

Control valves are less expensive and more durable

Low-pressure steam is easier to control

Sealing surfaces last longer due to lower temperatures and reduced thermal cycling

Steam trap size is minimized

While the heat exchanger size increases as the steam pressure decreases, the smaller trap and less expensive control valve may offset the additional first cost of the heat exchanger. The reduced flash steam losses and maintenance costs will almost certainly result in a lower life cycle cost.

What if Steam Pressure is Too Low?

Since the volume of steam is so much greater than that of condensate, a vacuum can occur when steam is condensed. In vented condensate return systems, we must break this vacuum to permit good condensate drainage. This is particularly important in air handling equipment, where exposure to air below freezing temperatures may cause the condensate to freeze. We use a steam vacuum breaker for this purpose.

The vacuum breaker is a spring-loaded check valve that opens at a low pressure, admitting air to break the vacuum. When the pressure in the condensing space exceeds the vacuum breaker setting, the vacuum breaker remains closed to prevent the steam from escaping.

Stay tuned for more on steam systems!