Steam Basics Part 8: Steam and Condensate Pipe Sizing Health Care Example

/By Chad Edmondson (JMP) and Norman Hall (RLD)

Our last two Steam Basics blogs examined steam and condensate pipe sizing. This week we’ll explore this topic using a health care office building as an example.

In this case, let’s say the engineer is designing a steam system for a new medical office building next to an existing hospital. The engineer has identified the following operational parameters:

The total load of the new building will be 4300 PPH, which includes a hydronic heat exchanger, a domestic water heater, and a 600 PPH sterilizer load.

The steam boilers in the plant are designed for 100 PSIG, but the operators have advised that they run at 75 PSIG.

An existing supply through the hospital tunnel to the new takeoff was determined to have 14 PSIG of pressure drop at full capacity, including the new 4300 PPH additional load.

There will be 80 feet from the new takeoff to the new PRV station.

The autoclaves have a maximum pressure of 50 PSIG. They will require 30 PSIG at the station and the heating and domestic water system design require 10 PSIG steam.

The drip trap for the PRVs requires a capacity with safety factors of 85 PPH.

Now, let's identify the steam PRVs and size the steam and drip trap condensate pipe.

STEP 1: Size the steam supply pipe

The new system will have a steam supply pressure of 75 PSIG – 14 PSIG = 61 PSIG at the takeoff. Using the Hoffman pipe sizing program we will use 4-inch schedule 40 pipe with 0.6 PSIG pressure drop per 100.

Since the PRV is 80 feet away from the new takeoff and the pressure drop is 0.6 PSIG per 100 feet, let’s use 60 PSIG as the steam pressure to PRV-1. We need a PRV for the autoclaves since the steam pressure from the plant may reach 75 PSIG as operated.

STEP 2: Select Pressure Reducing Valve (PRV) 1

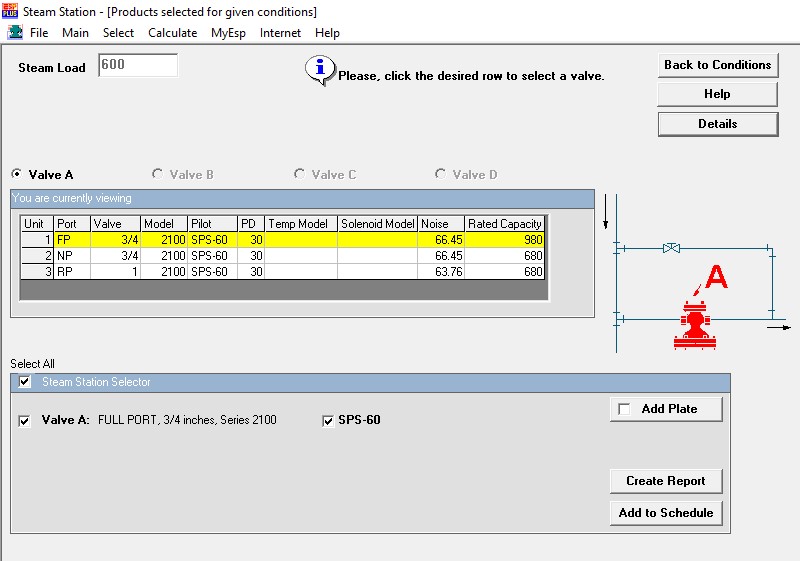

Pressure Reducing Valve (PRV) 1 is medium pressure with an inlet pressure of 60 PSIG and outlet pressure of 30 PSIG with a capacity of only 600 PPH. We enter these values into the Hoffman selection program as follows:

Our solution (shown below) is a pilot operated Hoffman Model 2100 3/4-inch PRV with a normal port (NP) and a SPS-60 spring pilot. We could use the full port model but it would be oversized for the load. The noise level is 66.5 dBA so noise is not an issue.

STEP 3: Select PRV-2

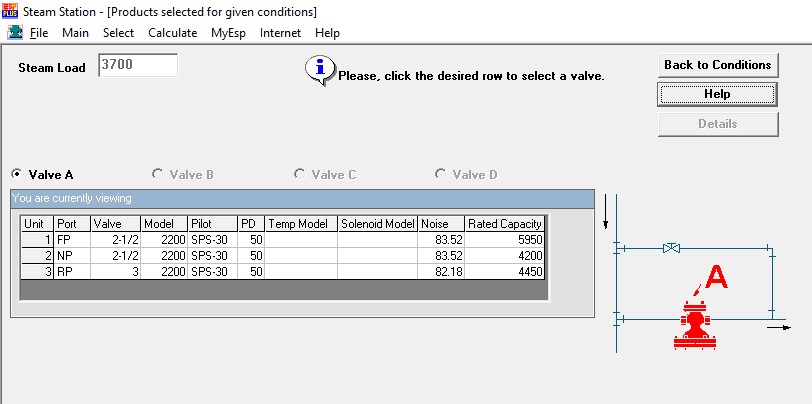

The second PRV will serve the hydronic heat exchanger and the domestic water heater. The load is 4300-600 = 3700 PPH. The entering steam pressure is 60 PSIG and the outlet steam pressure is 10 PSIG. We enter the values as we did before and the program generates the following:

The program has offered up some interesting choices for our PRV-2 selection. Let’s assume the hospital wants to limit noise to 83 dBA at the PRV station. The engineer could specify the 3-inch Hoffman Model 2200 with a reduced port (RP) design, which meets the lower noise requirement. This would be the most expensive valve but it would not require any additional noise attenuation. Keep in mind, the schedule must clearly identify the maximum noise level or the sales representative or wholesaler will quote the 2 1/2 - inch model, which is less expensive.

Another option would be to use the 2 ½ - inch Model 2200 with a full port (FP) design reducing valve and add a noise attenuation plate or insulation.

STEP 4: Inlet and outlet steam pipe sizing for PRV -1 and PRV-2

The pipe sizing required is as shown above. Using 6000 FPM as the maximum velocity, we could use 1¼-inch pipe but the pressure drop is 5.6 PSIG per 100 feet which seems high so we choosea 1½-inch pipe instead.

STEP 5: Size the drip trap pipe

The drip trap has a capacity of 85 PSIG and a minimum pressure of 60 PSIG. We size the trap as follows:

In this example, we experimented with a variety of pressure drops and the selections all came up as either ½-inch or ¾-inch. Either pipe size is correct. Some engineer offices keep the minimum pipe size at ¾-inch due to concerns over corrosion over time. The choice is subject to your office standards.

Selecting steam and condensate pipe sizes is a bit more complicated than hydronic pipe sizes, which is why the Xylem Hofmann programs are a handy tool to have. Next week, we will discuss steam trap selection.