Steam Basics Part 4: Vacuum Breakers on Steam-to-Water Heat Exhangers

/By Chad Edmondson (JMP) and Norman Hall (RLD)

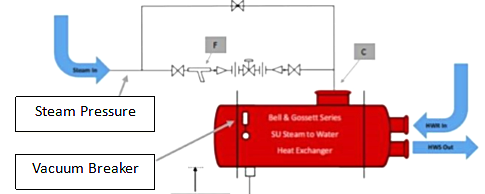

This week we take a look at the vacuum breaker on a steam-to-water heat exchanger. Steam-to-water heat exchangers, or steam heating coils with on-off or modulating control valves, require a vacuum breaker. This simple and relatively inexpensive device may save thousands of dollars in coil replacement costs.

Vacuum breakers should always be used on steam-to-water heat exchangers. They prevent condensate from being held up in the shell, which can lead to water hammer and tube damage.

Steam-to-water convertors, or heat exchangers, heat the water in the tubes by condensing steam in the shell. When steam is present in the shell, the steam trap is closed. When the temperature control valve closes, the heat exchanger shell becomes a closed vessel filled with steam.

When the steam condenses in this closed chamber, it creates a vacuum. This happens because the volume of steam is dramatically greater than the volume of condensate. If you completely filled the inside of a minivan with 5 PSIG steam and then condensed the steam to water, the water would fit in a 2 gallon pail. That's an immense volume change!

Normally, the condensate flows through the steam trap to a gravity return (0 PSIG). If a vacuum occurs in the shell, water can't flow from the lower pressure (vacuum) to higher pressure (0 PSIG), so the condensate remains in the heat exchanger. When the steam control valve opens, the steam tries to pass through the condensate, and this causes a "hammer." The water hammer in the shell will cause damage to the tube bundle. The image below shows damage to a tube caused by water hammer.

Water hammer damage on tube bundle.

An adjustable vacuum breaker can prevent the vacuum from occurring and allow the condensate to drain into the drop pipe to the trap. The vacuum breaker can be located anywhere between the control valve and the trap, but Bell and Gossett SU heat exchangers have a convenient ¾” tapping in the shell for the vacuum breaker.

Vacuum breaker allows condensate to drain into the trap.