New Pump Efficiency Standards Part 1: They Are Here -- Now What?

/By Norman Hall (R. L. Deppmann) and Chad Edmondson (JMP)

Heat pumps have them. Air conditioners have them. Even light bulbs have them. And now, for the first time in history, clean water pumps have them too.

We’re talking about efficiency standards, officially issued for pumps by the Department of Energy (DOE) on January 4, 2016. These new pump efficiency standards, which will take effect in 2020, include the following categories of pumps:

End suction close-coupled

End suction frame mounted/own bearings

In-line (end suction)

Radially split, multi-stage, vertical, in-line, and submersible turbine

The pump efficiency standards have been in the works for some time and are based on negotiations of a committee of manufacturers, efficiency advocates, and other stakeholders. In addition to being the first-ever national efficiency standard for pumps, the ruling also includes the first standardized test procedures for commercial and industrial pumps. The DOE established a Commercial and Industrial Pump Working Group (CIP) under the Appliance Standards and Rulemaking Federal Advisory Committee (ASRAC). We're proud to say that Mark Handzel, a longtime leader at Xylem Bell & Gossett, is a member of this working group and has been for many years.

What Are the Pump Efficiency Standards?

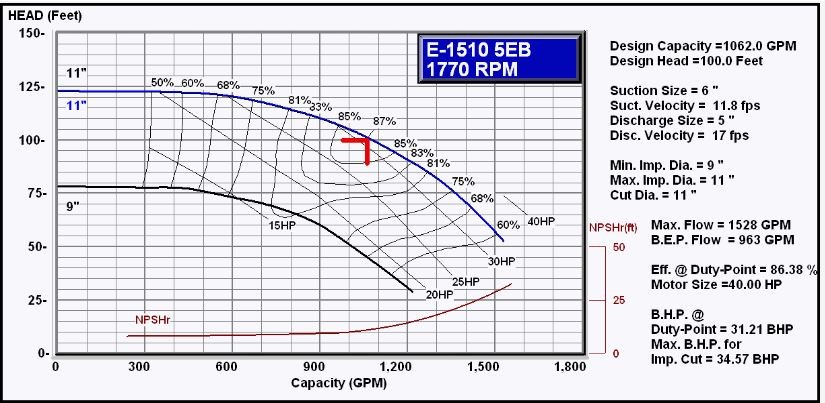

The standards apply to clean water pumps such as those used in HVAC systems. The standard refers to flow and head at “BEP” at full impeller diameter. “BEP” is the pump term for best efficiency point on the curve.

These are the specific sizes and capacity pumps that the standard will apply to:

25 GPM and greater (at BEP at full impeller)

459 feet head maximum (BEP at full imp)

Design temperature range 14 to 248 degrees

Pumps designed for 2 or 4 pole induction motors (3500 and 1750)

Pumps with non-induction motors to 4,320 rpm (rare in our world)

VTS 6 inch & smaller bowls (small vertical turbines)

ESCC and ESFM specific speed less 5,000

From 1 to 200 horse power, rated with and certified with full impellers

The new pump efficiency standards are expected to remove the worst-performing 25 percent of pumps from the market. Manufacturers must either redesign or polish existing pumps that do not meet the standard, or remove them from their product offering. But don’t worry – it’s unlikely that these new standards will leave engineers scrambling to find the right pump. Most manufacturers have been working towards these efficiency levels for many years, and some leading pump manufacturers have already assured their sales agencies that most of their pumps already exceed these requirements.

What Does the New DOE Standard NOT Include?

What the DOE did not address at this time are the larger double suction pumps. This larger horsepower group will be addressed in a later update. Also not included are fire pumps, self-priming pumps, sump pumps, and vertical turbine pumps with bowl sizes larger than 6” (which are most of the vertical turbine pumps we use in HVAC).

We’ll explore what these test standards really mean over the next few blogs, so stay tuned. In the meantime, if you're up for some not-so-light reading, download a full copy of the DOE’s Energy Conservation Program: Energy Conservation Standards for Pumps.