Modern Pump Selection Part 1: What Are Efficiency Islands?

/By Chad Edmondson

Most of us know and understand that the centrifugal pumps used in closed hydronic systems rarely operate at peak load. In fact, these pumps typically only operate at peak load about 5% of the time. So it doesn’t make a lot of sense to select a pump based solely on its performance at peak load. It makes more sense to select a pump based on a wider range of conditions, including peak load.

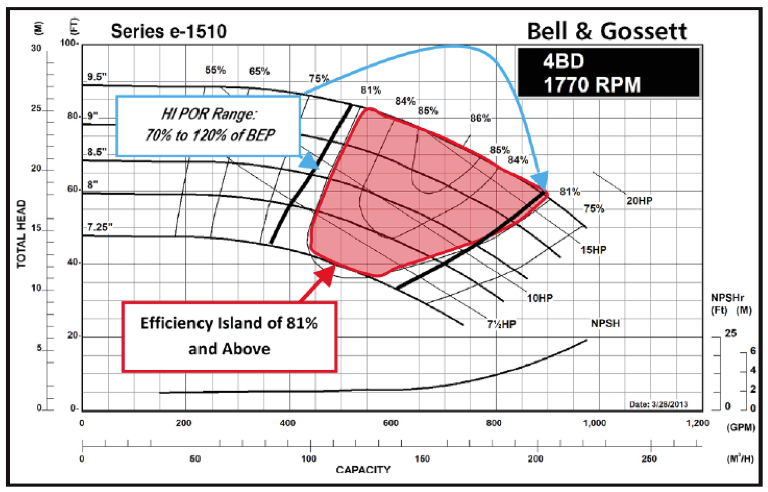

Such a selection will generally yield far more savings than a pump selection based on the singular sweet spot of Best Efficiency Point (BEP). Instead of focusing on that point where the system curve intersects with the BEP, we need to look at a broader operating range, the boundaries of which form what is called an “Efficiency Island”.

Efficiency Islands are bound vertically by the minimum and maximum impeller diameter performance and horizontally by the iso-efficiency lines, those concentric elliptical curves that “wrap around” the BEP. Iso-efficiency lines are based on what the Hydraulic Institute has deemed as the Preferred Operating Range for a given pump, which is defined as the flow range from 70 to 120 percent of the pump’s BEP.

In Figure 1, the part shaded in red represents the Efficiency Island for a particular pump.

Figure 1

How Efficiency Islands Interact with the System Curves

Efficiency Islands can be used in conjunction with system curves to select a pump that will operate efficiently over most of the system’s load profile.

We know that the pump will always operate at the point where it intersects the system curve. Of course, in most systems, the system curve is always moving, as valves close and open in response to demand. Therefore when selecting a pump we must consider the entire operating range of the system, which is defined by the control curve. (Figure 2)

Figure 2

If we transpose the upper and lower system curves on a given pump curve, as we have in Figure 3, it is apparent that the best overall operating efficiency will occur with pumps that have the deepest and widest efficiency islands. This essentially expands the cross section area between the control curve and the Efficiency Island. If high efficiencies are confined within a narrow flow range then there will be a rapid drop in pump efficiency as the impeller diameter is reduced. This is especially important to remember when selecting pumps with Variable Frequency Drives (VFDs) because VFDs enable pumps to operate as though they have various impeller trims.

Figure 3

Notice in Figure 3 that the design point is located just outside of the pump’s BEP. That’s perfectly acceptable since this pump moves back through the higher Efficiency Islands as it unloads, maintaining an efficiency of 82% even at 50% of the design flow of 750 GPM.

Stay tuned for more about how and why Efficiency Islands should be used when selecting pumps for today’s hydronic systems.