High-Volume, Low-Speed (HVLS) Fans Part 3: Design Considerations

/By Gary Holder

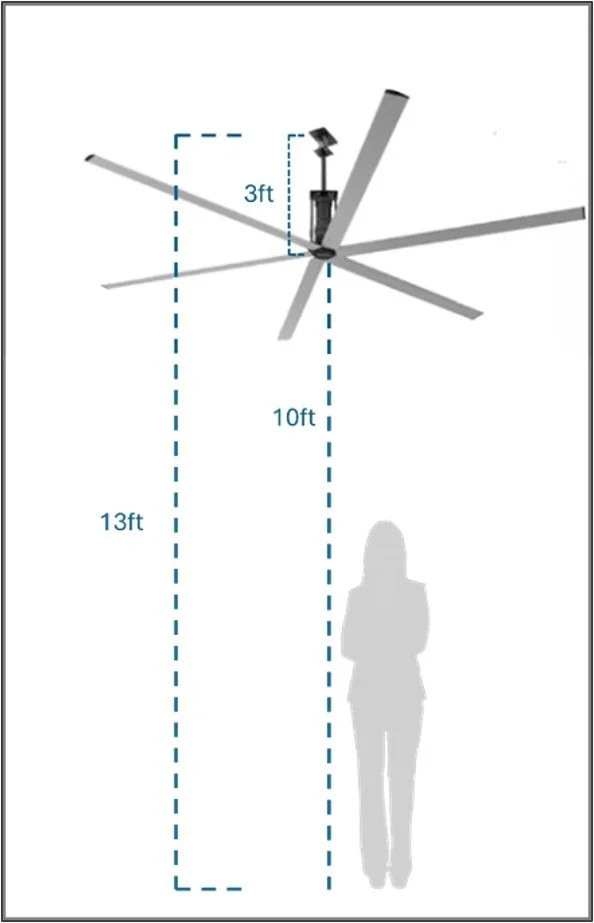

figure 1

So, you think HVLS fans may be the perfect solution for an upcoming project. But what sort of things should you consider as you approach this decision?

Spatial Considerations

Long before an owner or engineer begins the process of selecting an HVLS fan, they must first consider the space. HVLS have applications in a wide range of spaces, but there are a few limiting factors—most notably ceiling height.

HVLS fans are generally intended for open spaces with ceilings that are at least 13 feet high. (12-foot ceilings may be able to accommodate smaller diameter HVLS fans.)This height leaves sufficient room for a standard 3-foot drop from the ceiling to the blade fans and at least 10 feet between the fan blades and the floor. (Figure 1) (Table 1)

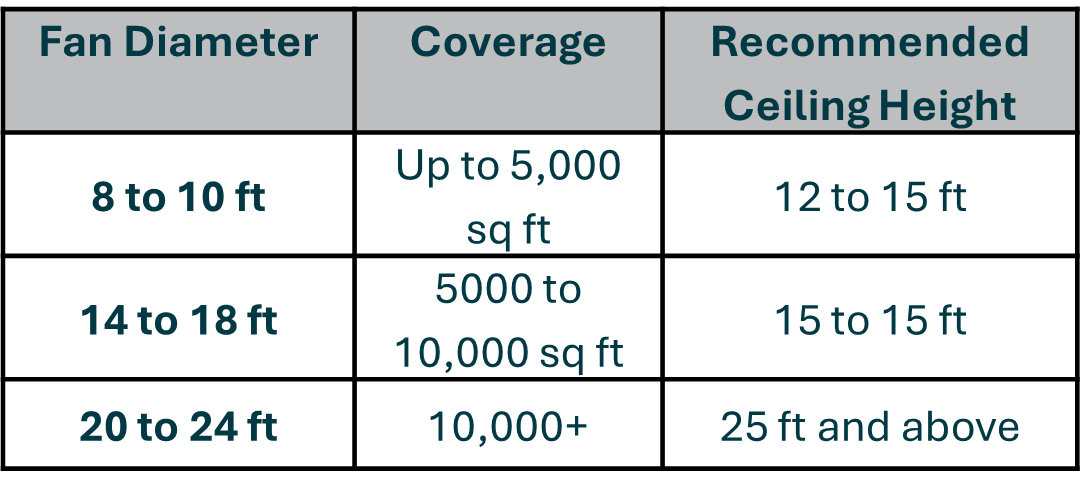

table 1

Horizontal clearances—those between fans and/or between the fan(s) and wall—should also be considered.

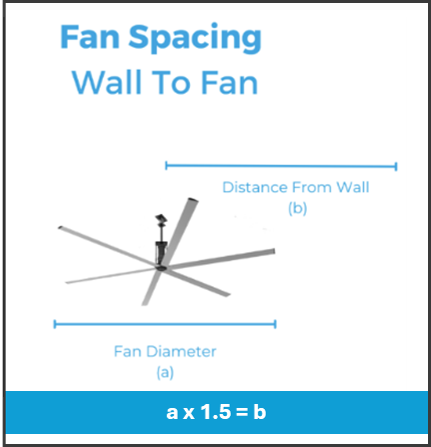

figure 2

The fan diameter, multiplied by 1.5, equals the required distance from the center of the fan to the wall. (Figure 2)

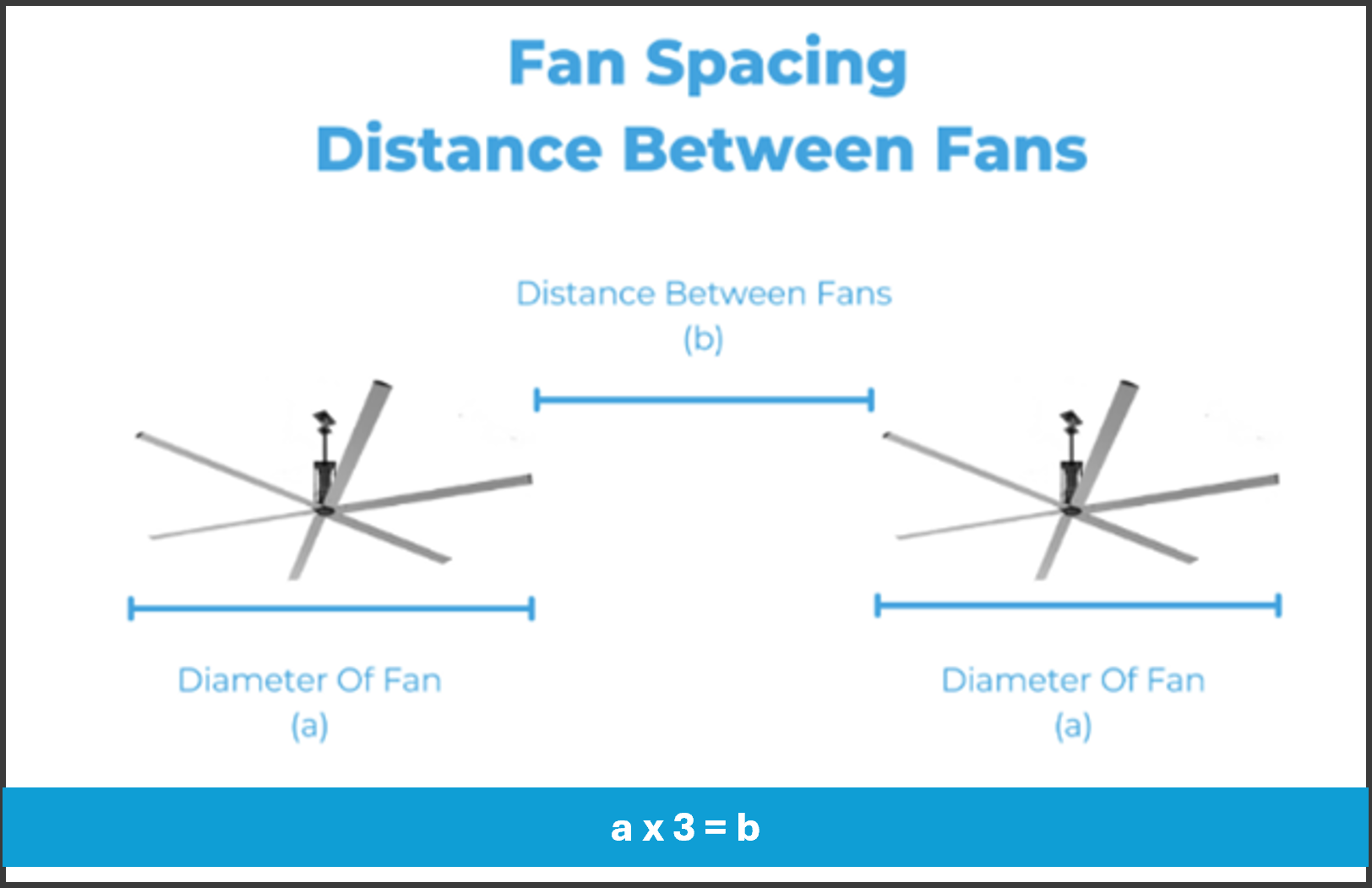

The diameter of the fan, multiplied by 3, equals the distance needed between fans. (Figure 3)

figure 3

HVLS fans are typically 6 to 24 feet in diameter. If your space cannot accommodate a fan of at least 6 feet, given the above clearance requirements, a standard fan is a more suitable choice. That said, there are numerous industrial, commercial, agricultural, and even residential spaces where HVLS fans are suitable.

Obstruction Interferences

You'll also want to take note of any obstructions that might interfere with installation, performance, or safety. These include any type of beams, lights, or other ceiling-mounted equipment. Tall shelving and narrow aisles between shelves can also restrict airflow, impacting the optimum size and placement of HVLS fans in certain areas—not that these are dealbreakers. HVLS fan manufacturers utilize air simulation programs to determine the optimal placement layout that mitigates these issues.

Sprinkler Systems

The National Fire Protection Association (NFPA) has specific guidelines regarding the installation of fans in facilities with sprinkler systems. The primary concern here is that in the event of a fire, the fans may impede the full dispersion of water. We will cover these NFPA guidelines later in this series.

Structural Support

Unlike regular-sized fans, HVLS fans cannot be directly attached to a standard ceiling joist. These fans often weigh 100 lbs or more and require robust overhead support, such as structural I-beams, steel rafters, or trusses. HVLS fan manufacturers have mounting systems designed specifically for various structural components.

Application Considerations

The type of space often dictates which type of fan design is best suited for your application. While nearly any type of space can benefit from the cooling, dehumidification, and/or destratification benefits that HVLS fans provide, some fan designs are more suited for certain applications. For instance, is the space a gathering place, such as a restaurant or bar, where people will be conversing and/or maybe sitting still for long periods of time? Is the ceiling height lower than 15 feet? If so, you’ll likely want to choose fans with a direct-drive motor to ensure quiet operation. A smaller diameter fan (8–14 feet) will provide adequate airflow without being intrusive.

Large, gear-driven fans are typically more suited for large industrial, agricultural, and warehouse spaces because they provide robust durability in harsh environments and can efficiently circulate massive amounts of air.