Condensing Boiler Plant Piping Design & Control Part 6: Boiler Cycling and Supply Delta T

/By Chad Edmondson

Identifying the stop and start range of a boiler system is a critical first step in controlling boiler staging and/or sequencing. This range defines what the boiler supply temperature is at full fire and what the supply temperature is at no fire. It is commonly referred to as the boiler supply Delta T. This value isn’t to be confused with the system Delta T, which can and should be much greater in a condensing boiler system.

A typical boiler supply Delta T is around 12 degrees. For the purpose of example, lets say we have a boiler supply water design temperature of 180F. Although the design supply temperature is 180ºF, the temperature will typically range from about 174ºF to 186ºF. In this case, if the boiler supply temperature (primary loop temperature) drops to 174ºF, then it is time to increase the fire rate of the boiler (if it isn’t at 100% yet), or perhaps bring on another boiler. If the supply temperature reaches 186ºF then it is time to reduce fire or cycle a boiler off.

Temperature Sensing and Control

Boiler controls sense supply water temperature and modulate/stage boilers based on the deviation from the set point. In between the maximum and minimum supply temperatures, a boiler control system may also be designed to reference outdoor air temperature and how fast the system is reacting to changes in fire rate. Boiler controls use PID logic to anticipate load changes based on the cumulative data they receive with regard to outdoor air temperature, supply temperature, and system reaction time. This keeps the control from initiating changes in fire rate prematurely and thus stabilizes boiler operation.

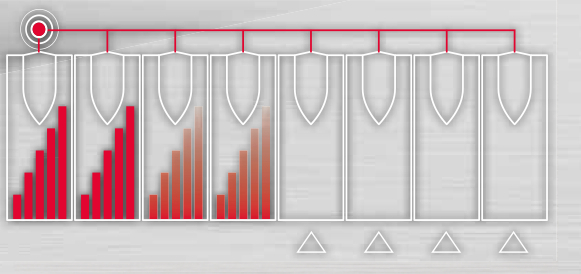

Cycling Pattern

Given typical load conditions, the boilers in our example will modulate as needed to keep the setpoint at or very near our setpoint of 180ºF, the secondary loop “taking out” btus as needed to satisfy demand. However, once the load is satisfied, the boiler supply loop temperature will inevitably start to rise since no btus are being removed. This is the point at which the system starts to recognize it’s time to cycle off. Conversely, there will be a point at which the boiler supply loop temperature begins to approach its lowest temperature threshold and an additional boiler or boiler stage will be needed. These two points define the start and stop range of the boilers.

Using the same example of a boiler system with a set point of 180ºF and a 12 degree Delta T, this is a typical cycling pattern: