Cooling Tower and Condenser Water Design Part 2: The Impact of Wet Bulb on Cooling Tower Performance

/By Chad Edmondson

How do you evaluate the performance of a cooling tower? What factors impact how effective a cooling tower will be in a given application? To get to the bottom of either of these questions – which are essential questions to ask when sizing a cooling tower – it’s important to understand the impact of the ambient wet bulb temperature on cooling tower performance.

Let’s forget about mechanics for a moment and just picture yourself on vacation in sunny Las Vegas, poolside on a 95°F day. It’s HOT, so you jump into the pool to cool off. When you return to your lounge chair, your body cools as the water from the pool evaporates into the air. It evaporates quickly and thoroughly because the dry air of Las Vegas soaks up the moisture from your body like a sponge. And each drop of water that evaporates represents a tiny measure of heat that is carried away from your body to the atmosphere.

That’s how a cooling tower works! Only instead of carrying heat way from your body, a cooling tower transfers heat away from the condenser water loop in a chilled water plant.

It's the Humidity!

Now let’s say that instead of Las Vegas, you’re vacationing in Panama, Florida. Again, the temperature is 95°F, so you jump in the pool. When you return to your chair, you do feel cooler for a brief time, but pretty soon your sweating again. The water is evaporating from your skin, just as it would evaporate in a cooling tower, but because the air in Florida is substantially more humid than in Las Vegas, less evaporation is taking place. That means less heat is being transferred from your body to outside air. So, while the air in Las Vegas is like a dry sponge soaking up moisture from your body, the air in Panama, Florida is like a damp sponge, and it can only soak up so much additional moisture because it is already wet.

You’ve just had your first lesson on the impact of wet bulb temperature on cooling tower performance! Cooling towers are sized based on the design wet bulb temperature of a given region because it is the wet bulb temperature that determines how effective they will be at releasing heat into the atmosphere.

But what is wet bulb exactly?

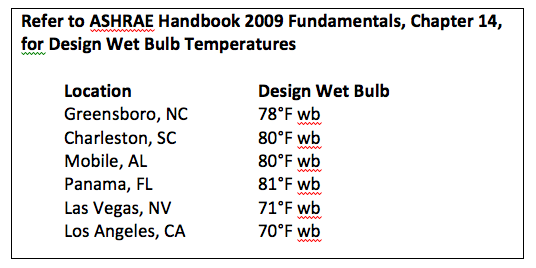

The wet bulb temperature is the lowest temperature that can be reached under the current ambient conditions by the evaporation of water. The actual air temperature (dry-bulb) and the humidity, or the amount of moisture in the air determines what the wet bulb temperature is. Therefore, certain regions of the country will differ in their design wet bulb temperature. (See Chart A).

Chart A

Cooling Tower Ton Versus Evaporator Ton

In terms of cooling that can be achieved through the use of cooling towers, a “nominal ton” is defined as 3 GPM of water, cooled from 95ºF to 85ºF at 78ºF wb. It is important to note that a nominal cooling tower ton is 15,000 Btu/hr whereas an evaporator ton is 12,000 Btu/hr. This comes from the assumption that the compressor generates 3,000 Btu/hr in a typical air conditioning application that the cooling tower has to dissipate.

The word “nominal” simply refers to what is typical of most conventional HVAC designs in most parts of the country. However, we all know that certain parts of the country are far more humid than others, so when designing a cooling tower system, it is important to look for the design wet bulb temperature for your region. Typically cooling towers can afford to be smaller in the arid southwest. Or, relating to our “human” example above, a wet giant will release more heat into the air through evaporation than a wet child. Why? Because the giant has more surface area! But neither the wet giant nor the wet child is going to give up as much heat on a typical summer day in Panama, Florida, as they would on a typical summer day in Las Vegas.

For more information about cooling tower and condenser water design, as well as many other hydronic HVAC topics, be sure to check out our online training video series!