How to Read a Pump Curve - Part 3

/Factors that Impact Centrifugal Pump Efficiency

By Chad Edmondson

Pump selection can have dramatic impact on the overall operating cost of a hydronic system. Consulting several pumps curves prior to the selection of a pump is the key to minimizing these operating costs. In this blog we will discuss the factors that impact pump efficiency and how pump curves can be used to take the guesswork out of efficienct pump selection.

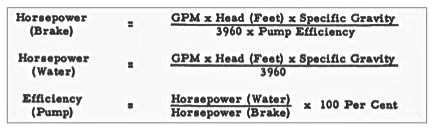

First, it is important to understand what pump efficiency is. Pump efficiency is the ratio of energy delivered by the pump in liquid horsepower to the energy supplied to the pump shaft in brake horsepower. So, a pump that delivers 75% efficiency at a given point on the pump curve is converting 75% of the brake horsepower it uses into hydronic energy or liquid horsepower. Table 1 shows how brake horsepower and water horsepower are calculated and how both are used to determine pump efficiency.

Table 1

A pump’s efficiency is impacted by several factors, all of which can be known by consulting a pump curve. These factors include:

Flow and Head. It is fairly clear by examination of virtually any pump curve that pump efficiency will varies depending on the total head (vertical axis) and the flow (horizontal axis). By knowing the dominant flow and head range that the pump will typically be pumping at, you can select a pump so that its primary operating range falls within or near its best efficiency range. Note that every pump curve has a Best Efficiency Point (BEP) at a given impeller trim. Any point to the left or right of the BEP represents a drop in efficiency.

ASHRAE recommends pump selection between 66% to 115% of flow at the BEP. Within this range the combined effects of circulatory flow, turbulence, and friction losses are minimized. However, 85% to 105% of flow is the preferred range of for pump selection. (See Figure 1)

Figure 1 ©ASHRAE, www.ashrae.org. 2012ASHRAE Handbook-HVAC Systems and Equipment.

Impeller Size. Change the impeller in a given pump and you will change that pump’s efficiency. Pump efficiency is greatest when the largest possible impeller is installed in the pump casing. This is because of the fluid that escapes through the space between the tips of the impeller blades and the pump casing.

Vibration. Pump impellers are subject to axial and radial forces, which increase as the pump operates further away from the BEP shown on the curve. The deflection of the pump shaft increases the amount of vibration, which in turn can diminish the efficiency of the pump.

Pump Size. Pump efficiency tends to increase with larger pump size. This is because the losses associated with bearing, mechanical, and internal hydraulic friction decrease in proportion to the required brake horsepower to drive the shaft as the pump gets bigger. That said, it is best to avoid over-sizing pumps in a given system since this will greatly decrease system pumping efficiencies.