How to Pick a Centrifugal Pump Part 6: Internally Vs. Externally Flushed Mechanical Seals

/By Chad Edmondson

Whether you install or design hydronic HVAC systems, you are probably aware that pump seals play a vital role in the operation of pumps and owner satisfaction. Unless you’ve ever had the opportunity to get up close and personal with a disassembled pump, the seal functionality and materials may remain a bit of a mystery. Today, we’re going to demystify these multi-piece assemblies and explain the differences between the types of seals normally used in HVAC Centrifugal pumps.

The evolution from Packing to Mechanical Seals

Pump impellers are mounted on pump shafts which penetrate the pump casing or volute. That point where the shaft enters the hollowed out “wet” portion of the volute would be a source of constant leakage if not for the pump seal.

A hundred years ago, most pumps relied on packing to prevent leakage from the pump while allowing the shaft to rotate freely. This type of packing or packed seal started out as an area in the pump referred to as a box where the packing material was pushed or stuffed into. These old technology pumps were called “stuffing box construction”. Fifty years ago the technology was improved and the packed seal consisted of several rings of braided yarn and graphite packing material that encircled the shaft and resided in the old “stuffing box.” This packing material was firmly compressed by a packing gland to prevent system water from leaking out of the pump casing.

Because the friction between the packing material and the shaft created so much heat, packed seals required quite a bit of lubrication. This lubrication came by way of system water that was routed from the discharge side of the pump, flushed across the packing, and then dispelled out of the pump. This created an “open” system, one that used and then leaked flushing water on a regular basis. The “leaking” of water was required and dripped out of the pump at about one drip per second. This water, of course, had to be replaced with make-up water which meant introducing more air to the system and increasing corrosion.

In addition, packed seals had to be regularly adjusted to maintain the correct amount of lubrication by manually tightening the gland, creating excessive wear and tear on the components. Decades ago, this type of seal was the standard for most industrial pumps and is still used today for some industrial applications.

Today, mechanical seals are the standard in HVAC pumps. Mechanical seals do not have any type of leakage; rather an integral spring provides the pressure against two highly polished faces to seal the pump. Even competitors to B&G pumps with old style pump volutes designed with exterior stuffing boxes were retrofitted to accept mechanical seals. That’s why today in the HVAC systems, there are two types of mechanical pump seals – those designed for older style with an external flushing line and those mimicking the B&G designed internal flushing style.

Externally Flushed Mechanical Seals and Why They Should Be Avoided

Externally flushed seals operate similarly to other mechanical seals, but are designed to be installed in the dry space of the volute, just like older style packed seals. Thus, they require external lubrication to prevent overheating from friction between the shaft and rotating and stationary seal parts. This lubrication is provided by capillary type tubes that route water from the discharge of the pump to the mechanical seal, thus making the system closed as opposed to externally lubricated packed seals. There are three downsides to this design.

The first concern is simply the size of the flushing line. These are normally ¼” or 3/8” copper tubing. If the water quality starts to build up sediment in the lines or there is field damage to the lines, there will be a restriction to the flow rate. Reducing the flow rate from what the manufacturer engineered will reduce the seal life.

The second concern is again related to water quality. The seal faces are highly polished surfaces. Any grit that gets between the faces etch the faces which will cause premature failure at best and a leaking seal at worst.

The third concern is the amount of water being flushed across the seal to reduce the heat build-up caused by friction. The amount of flow rate is subject to the pressure difference between the inlet and outlet and the pipe friction loss. The manufacturer designed the pipe size and flow rate to match that needed for the pump. What happens when we put a variable speed drive on the pump? The suction pressure in a closed system remains fairly constant but the discharge pressure drops. The flow varies as the square root of the difference and the flow drops. This may not be much of an issue in a chilled water system but could cause a reduced seal life in a heating system.

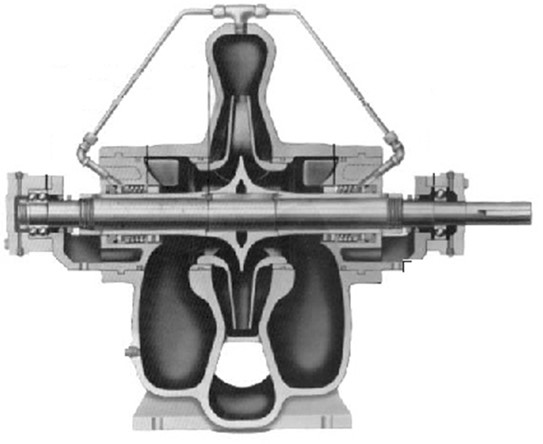

The cutaway below shows these tubes on either side of a typical external mechanical seal split-case double suction pump. Notice that they feed directly into the stuffing box where the seal is contained.

Externally flushed mechanical seal on split-case double suction pump.

Internally Flushed Mechanical Seals and Why They Are Better

Just like externally flushed mechanical seals, internally flushed mechanical seals prevent water from escaping the pump casing while also allowing the pump shaft to spin freely. However, the design is more sophisticated and more reliable.

Internally flushed seals on a horizontal split-case pump

Internal mechanical seals are located closer to the impeller of the pump, in an area that is filled with water upon start-up. Thus, they are essentially submerged in the system water and are exposed to about 25% of the pump flow. This is valuable because: (1) it eliminates the need for any exterior lubrication and tubing, and (2) the higher velocity of the water surrounding the seal provides better flushing, thus increasing the seal life.

In an externally flushed seal, the tubing forces the entire required flow rate at a very high velocity directly at the seal. The internally flushed seal is in essence sitting in a bath filled with water. Why does this increase seal life? Imagine you are sink washing a piece of your Grandmother’s fine china and her water quality is terrible. There is a great deal of sand in the water. Would you use a high velocity spray to clean it or soak it in a tub of water and gently swirl the washcloth around it? Like fine china, centrifugal mechanical seals are expensive to replace and are often exposed to water with a lot of debris.

While pumps designed for externally flushed seals are still available today, we recommend you specify and demand pumps with internally flushed mechanical seals for hydronic HVAC systems, whether the pump is part of a brand new installation or is a replacement for an existing pump with an external seal. Internally flushed seals require less service and help extend the life of the pump.