How to Pick a Centrifugal Pump Part 5: Choosing a Single or Double Suction Pump

/By Chad Edmondson

What are the differences between a single and double suction pump and what advantages does one have over the other? That’s what we are exploring this week.

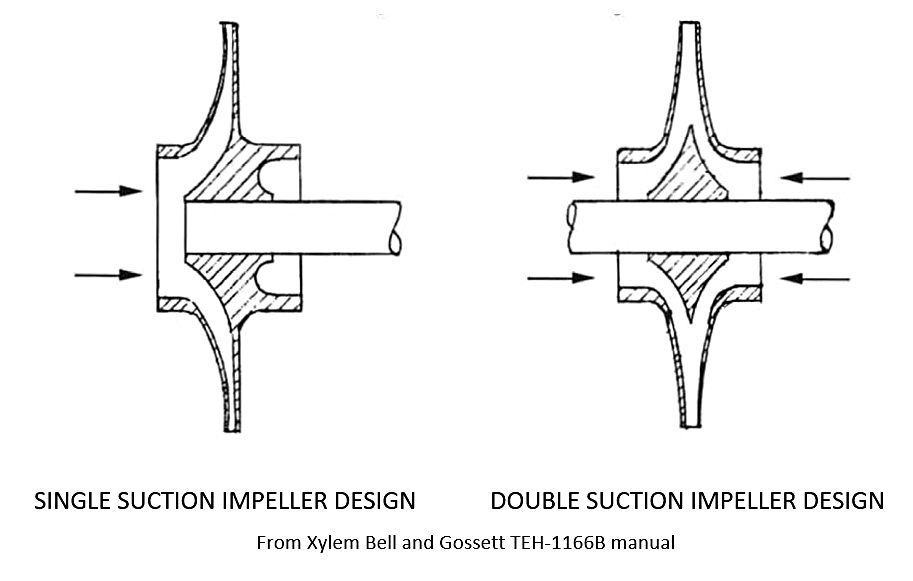

The central difference between a single and double suction pump is the latter has an impeller designed to draw flow through it from both sides. This double suction design eliminates the axial forces on the impeller which allows for higher flows than single suction.

As a result, double suction pumps are also less vulnerable to the wear and tear caused by axial thrust, which occurs when water enters the impeller. Since water enters both sides of a double suction impeller, one side effectively cancels out the axial thrust of the other – assuming that flow is even on both sides. But since that is not always the case, double suction pumps have inboard and outboard bearings to absorb some of this load. These bearings can afford to be smaller than those on single suction pumps simply because there is better balance across the shaft of a double suction pump.

Double or Single Suction?

We typically recommend a double suction pump design for HVAC applications around 2,000 GPM or an 8” pump size. When it comes to applying a double suction pump we suggest:

(1) Selecting a pump with the shortest shaft span possible to minimize shaft deflections.

(2) Specifying based-mounted pumps with flexible couplers whenever possible. These pumps are easier to service than double suction inline pumps, which require the motor to be removed to periodically replace worn out throttle bushings.

Generally speaking, a double suction pump can be twice the cost of a comparable single suction design. Obviously, pricing is positive when it comes to single suction pumps. They are also easier and less expensive to maintain. On the other hand, double suction pumps last longer – as much as 30 years. The double suction design eliminates the axial forces on the impeller which allows for higher flows than single suction.

Different Types of Double Suction Pumps

When it comes to selecting a double suction pump, there are three types to choose from, including:

Horizontal Split Case – These pumps have a “clam shell” type volute that is split horizontally across. The top part of the volute is bolted to the bottom. It has been around for close to 100 years. Because the pump is split horizontally, there is significantly more service time and rigging required to lift the heavy top of the pump. Watch for very old specifications. Many people called double suction pumps “split case,” all of these pumps have split casings. It just depends on whether the case is split horizontally or vertically.

Horizontal Split Case Double Suction Pump

Vertical Split Case – Vertical split case pumps are split vertically with a removable cover plate at the end-suction that can be removed to service the bearings or pump shaft.

Vertical Split Case Double Suction Pump

Vertical split case pumps come in 3 different configurations as shown here that can save floor space depending on the building piping configuration requirements:

Configurations of vertical split case pumps

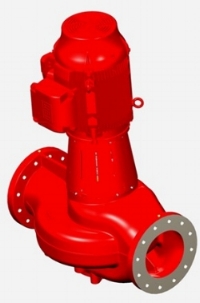

Double Suction Inline – These pumps can be quite large and are typically double suction when the piping flange size is over 12 inches.

Vertical Inline Double Suction Pump

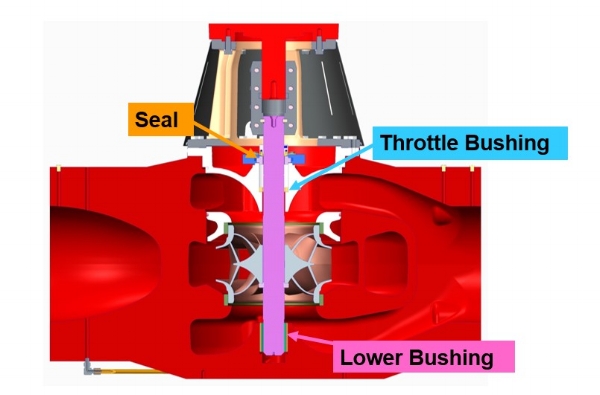

Double suction inline pumps have bushings (no moving parts) instead of bearings, which must be changed whenever the pump seal is services, as they are susceptible to wear and tear. This is significant because the motor of these pumps must be lifted off the top to change out the bushings, or service the pump seal.

Vertical Split Case or Horizontal?

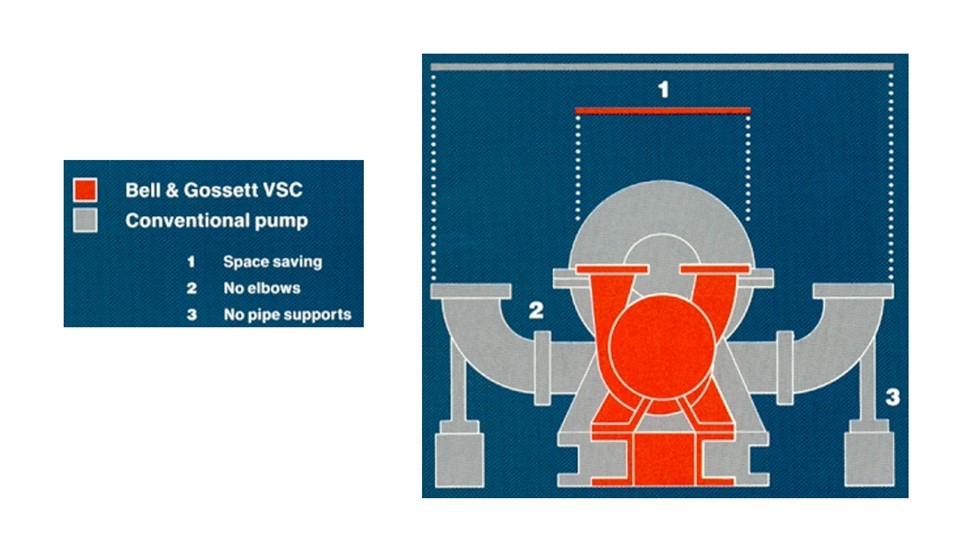

All other things being equal, a very good case can be made for choosing a vertical split case pump over a horizontal split case pump. First, vertically split case pumps can and often do take up far less space, depending on the orientation of the pipe connections. Assuming the suction and discharge piping can be vertical, it’s easy to see from the following diagram why this is so:

Second, the shorter distance between the bearings on a vertical split case pump helps reduce shaft deflection and thus helps lengthen the life of the pump:

What’s the take out of all this? When higher capacities are required, double-suction pumps can be a longlasting solution. Also, specifying the shortest shaft helps lengthen the life. Double suction pumps come in a variety of configurations to accommodate various piping connections. Vertical split case double suction pumps are more space efficient than horizontal split case double suction pumps – especially when the discharge and suction piping comes vertically from above. Double suction inline pumps are also an option, but are only available in very large sizes. The weight of the motors (which must be lifted away) make servicing these pumps problematic.

Next week we talk about externally versus internally flushed seals!