Avoiding Pump Cavitation in Open Systems: How to Determine NPSHA and NPSHR

/By Chad Edmondson

In our previous blog we explained the physics behind that noisy, destructive phenomenon known as cavitation – the result of too little NPSH at the suction of the pump. Today we’re going to dig a little deeper into NPSHA (Available Net Positive Suction Head) and NPSHR (Required Net Positive Suction Head).

If you read our last blog, you may have been surprised to learn NPSH available can vary greatly between systems and sometimes within systems. This has to do with the dynamic relationship between pressure, temperature, and the boiling point of water. Variances of any of these can impact how much NPSH is available, so it is important to select a pump that requires no more than the system can give at any given time. In other words, available NPSH must be greater than the required NPSH of the pump.

Where is the lowest pressure of the system going to occur? At the eye of the impeller.

The required NPSH of a pump increases with the flow. On the other hand, the larger the pump is, the less pressure drop inside the pump because of the larger impeller eye, which translates into a lower NPSHR. So, if two differently sized pumps are picked to develop the exact same flow rate, the smaller pump will have a higher NPSHR than the larger pump at the same flow rate.

Determining NPSHA

What are the factors that impact the available NPSH? There are four:

Type of fluid being pumped (Different fluids have different specific gravities, which impacts pressure

Location of tank (if open system) with respect to sea level

Temperature of the fluid being pumped

Vapor pressure of the fluid being pumped

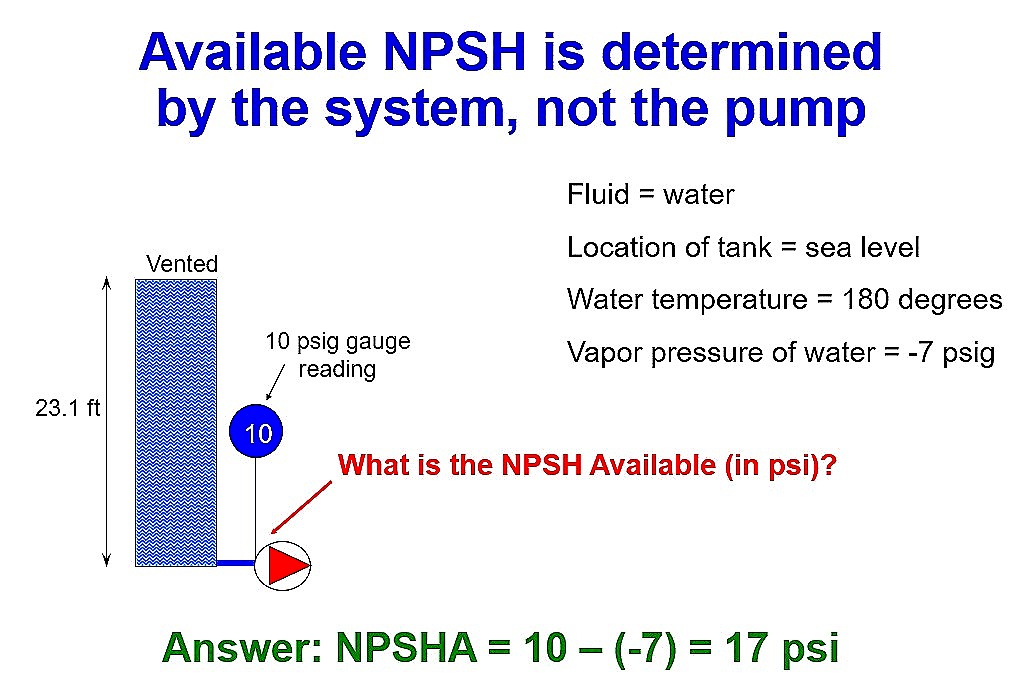

Example:

So let’s say we have an open vented cooling tower, conveniently located at sea level with a static height 23.1. The water we are pumping is 180°F and has a vapor pressure of -7 psig at sea level.

23.1 ft. of water column at sea level is equivalent to 10 psig, which is what our pressure gauge, located at the pump suction, would read because:

[(23.1ft./2.31ft/psi) x 1SG(specific gravity of water at sea level) = 10psi]

That’s how much NPSH we have at the suction of the pump. But we also have an additional 7 psi to work with because the vapor pressure of water at sea level at 180 degrees is -7 psi. As long as we keep the water above -7 psi the water won’t boil and therefore the pump won’t cavitate. Thus, we have a total NPSHA of 17 psi.

What about the required NPSH? How do we know what that is?

Required NPSH (NPSHR) is all about the pump you choose. Every pump has a specific NPSH requirement that is based on the pressure drop between the pump suction and the eye of the impeller. Typically this information can be found on the pump curve for a specific model. Just remember that the further your pump operates to the right of the curve, the higher the required NPSH will be.