Steam Basics Part 12: Steam & Condensate Strainers

/By Chad Edmondson (JMP) and Norman Hall (RLD)

In continuation with our series on steam basics, today we want to take quick look at strainers and their application in steam systems. It may come as a surprise to some that strainer specification for steam systems is different than specification for hydronic systems.

Normally, strainers are placed before control valves on the steam side of the system, and before traps and condensate pumps on the condensate side of the system. While steam is generally cleaner than condensate, even small amounts of dirt in control valves can cause major issues. Dirt can keep control valves from closing, and even small particles of dirt can accumulate and plug ¼” sensing lines around controls and pressure reducing valves.

In condensate systems, the concern is less about dirt and more about particles of rust or flakes of steel pipe becoming loose due to the aggressive nature of the condensate. (Carbon Dioxide, CO2, in the steam becomes carbonic acid when the condensate starts to cool.) If fine mesh strainers are installed in the condensate piping system, they may clog up quicker causing more maintenance and possible operational issues.

Mesh, Perf, and Diameters: What does it all mean?

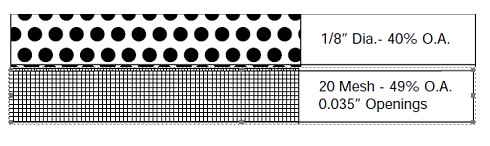

In the world of strainers, we use three terms to describe the opening sizes of the screen. Mesh screens are normally the finest. A 20 mesh screen has 20 openings every inch of screen. Perf is short for perforation and refers to the size of the hole in the screen. A .062 perf screen has .062” holes or 1/16” holes. Diameter is a term sometimes used instead of perf.

Steam and Condensate Strainers

There are standard strainer screens and optional strainer screens available. For steam systems, we recommend you specify 20 mesh screens for strainers up to 2”, .045 perf from 2-1/2” to 6”, and .062 perf above 6”.

The steam traps in condensate systems require larger openings. We suggest .045 perf up to 2” and .125 perf above 2”. Condensate pumping systems normally have a strainer at the inlet of the condensate tank. Your client is best served if this is a basket strainer. Normally condensate units serve many areas or a main heating heat exchanger system. The strainer used here should have a large dirt pocket with a vertical serviced basket. These strainers are normally cast iron construction. An example of the Xylem Domestic Brand is shown below.

Xylem Condensate Pumping System

You may ask why we change the size of the hole in small pipe versus larger pipe when it is the same steam. The balancing act is to avoid too much maintenance while still protecting the traps and valves. As traps and control valves get larger, so does the orifice size. If we put fine mesh strainers throughout the system, they will plug more frequently and increase the number of times maintenance must clean them. For these reasons the size of the hole changes with the size of the pipe.

We offer a variety of steam and condensate strainers from Keckely, Hoffman, and Domestic.