Steam Basics Part 10: Understanding the Thermostatic Portion of a F & T Trap

/By Chad Edmondson (JMP) and Norman Hall (RLD)

Steam traps play a very important role in steam systems. Last week, we discussed how the float portion of a float and thermostatic (F&T) steam trap operates. This week, we will explore the operation of the thermostatic portion of the steam trap.

Why is the thermostatic portion of a float and thermostatic (F&T) steam trap important?

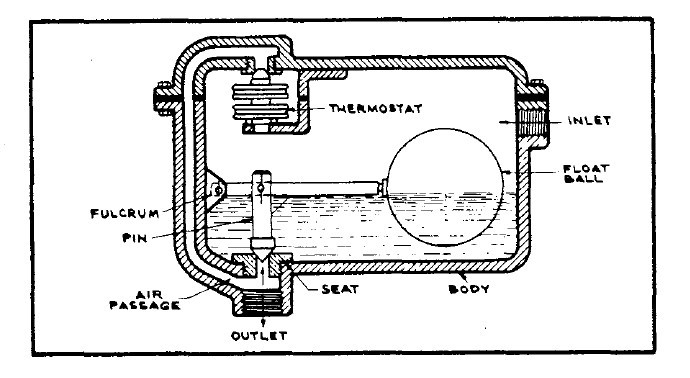

The “float and thermostatic” or "F&T" steam trap uses a float and lever system to operate. It also employs a thermostatic element. Here is a cross section drawing of a F&T trap from the Xylem Hoffman Specialty Technical Manual TES-375A.

FLOAT AND THERMOSTATIC TRAP

It is a simple scientific fact that two things cannot occupy the exact same space at the same time. It follows that in order for steam to enter a heat exchanger, some of the air inside the steam exchanger must be removed. The large volume of air present in the heat exchanger shell when the steam control valve opens must push through the trap to make room for steam to enter the shell.

In the last blog we learned that the float and thermostatic steam trap is normally closed. So how does the air get pushed through a closed steam trap? This is the job of the thermostatic element in an F&T steam trap. The thermostatic element, which consists of a bellows with a pin attached, is normally open. When the hot steam enters the trap, the bellows expands and the vent closes. Hoffman sizes that element to match the intended capacity of the steam trap. The larger the capacity, the larger the thermostatic vent.

What if the thermostatic portion of a float and thermostatic (F&T) steam trap fails?

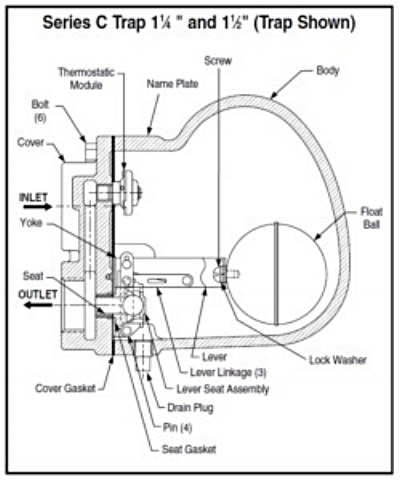

The cutaway detail of one Hoffman F&T steam strap is shown below. Notice that the thermostatic bellows is internal to the trap. If the bellows fails open, steam will pass through the opening to the outlet. This will waste energy and possibly cause steam hammer in the condensate return pipe.

If the thermostatic bellows fails closed, air will not be vented and there will be improper heating. There are simple checks for the heating technician in the Hoffman installation, operation, and maintenance manuals to rectify this situation.

One final note on thermostatic vents in F&T steam traps. Larger (2-1/2”) traps have an external vent. This vent opens and closes when the temperature control valve cycles. It will spit vapor during the cycles. It may leak a bit when closing and if it fails open or if debris is present, steam may escape. These vents should be piped to the gravity return pipe. If this is not possible then the vent pipe should go to a drain with a piping seal trap.

We select and F&T trap for our heat exchanger example because we have a modulating control valve. This is advantageous in this type of application because of the fast venting of air using the thermostatic vent and also the continuous modulation of the trap. Removing air from the trap is critical to proper operation with cycling applications. If the air is not removed, the condensate cannot enter the trap and we may back up condensate into the heat exchanger, causing damage to the tubes. Modulation is important because this application has a wide variety of capacities from design all the way down to a couple percent of design load.