Solving Balance Issues with A Differential Pressure Controller

/By Chad Edmondson

What are your options when unbalanced circuits in an existing hydronic system are creating comfort issues due to underflow or overflow through coils? We just spent the last twelve blogs describing the various methods for balancing a start-up system but do those same methods apply to existing systems and retrofits?

The short answer is yes; however, they aren’t always affordable or even practical. Try finding locations for automatic flow controllers or pressure independent control valves at every terminal unit in a 20-story office building and you’ll see what we mean. Fortunately, many of these problems can be addressed in stages, by installing adjustable differential pressure (DP) controllers on problem circuit(s).

What Does a DP Controller Do?

Pressure fluctuations are an inherent part of every hydronic HVAC system. If these pressure fluctuations are not addressed, they will most certainly create an imbalance in flow. This commonly occurs in large systems where one circuit, riser or wing of a building is located far away from the pump. As a result, distant coil(s) may be starved of flow under full load conditions, with the majority of the flow occurring at the nearby coils. Or, if flow limiters are installed on distant circuits, pumps may ramp back so much during low demand periods that the closest circuits get starved. In either case, you’ve got a problem.

DP controllers stabilize these pressure fluctuations and can be installed where they are needed with very little disruption to the system. They operate to maintain a constant differential pressure over the load (a branch of several fan coils, for example).

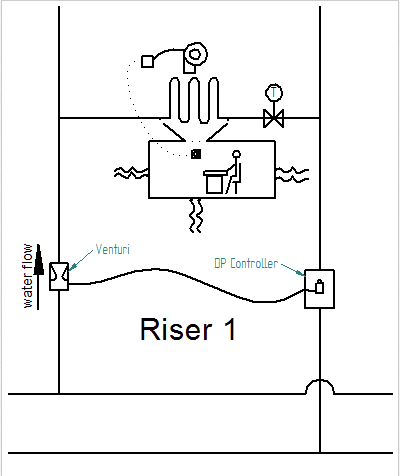

The DP controls the pressure between the controller itself and another point in the system from which the pressure is transmitted to the controller though a capillary tube. (Figure 1)

Figure 1

In a typical system, the DP controller would be installed on the return side of the circuit (most likely the one closest to the pump) and would be linked by a capillary tube back to a Venturi upstream of the coil(s). The DP controller absorbs excess differential pressure between the location where it is installed and the upstream location where the capillary pipe/tube is connected. This allows the differential pressure across the circuit load to remain constant so the control valves can effectively operate over their respective control range.

The beauty of this solution is that it allows for simple and systematic problem solving. One circuit can be fixed without disruption of other circuits because the installation of the DP controller and Venturi effectively isolates it from the other circuits.