Cooling Tower Suction Piping Guidelines

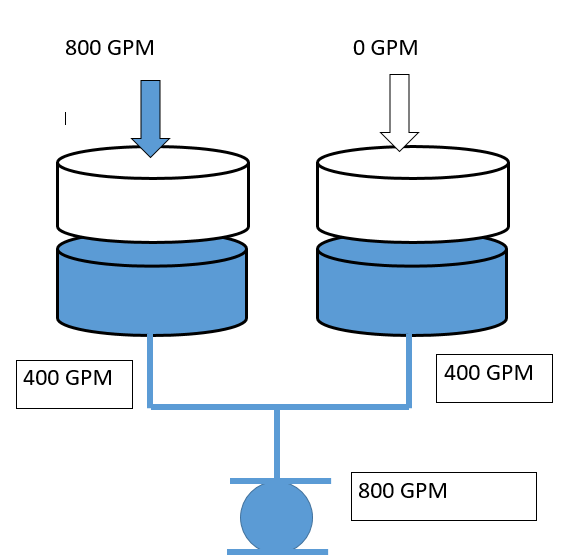

/When designing cooling tower suction piping, it is absolutely critical that engineers have sufficient NPSH to the condenser water pump and avoid any piping design errors that could cause air to come out of the pumping solution. If either of these becomes a problem…

Read More